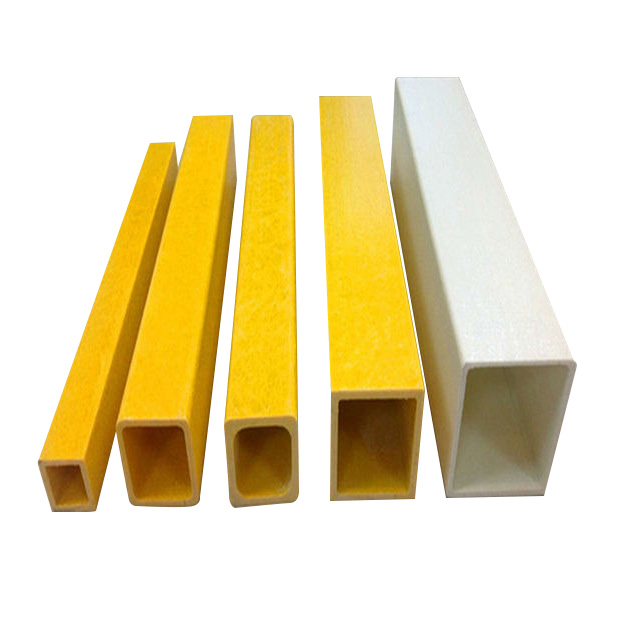

FRP (Fiber Reinforced Plastic) Special-Shaped Parts ~이다 custom-designed composite components made to meet specific structural, functional, or aesthetic requirements. Unlike standard FRP profiles, these parts are manufactured in complex shapes and geometries using molding, pultrusion, or filament winding techniques.

제품 성능 소개

FRP Special-Shaped Parts are widely used in industrial, marine, automotive, aerospace, and construction applications where lightweight, corrosion resistance, and high strength are required. These components are often customized for unique engineering projects, replacing traditional materials like metal, wood, or concrete.

2. Conventional Specifications & Dimensions

Common Specifications

| 사양 | 세부 |

|---|---|

| 재료 | Fiberglass Reinforced Polymer (FRP) |

| 수지 종류 | Polyester, Vinyl Ester, Epoxy, Phenolic |

| 색상 옵션 | Gray, Yellow, Green, White (Customizable) |

| 표면 마감 | Smooth, Textured, Gritted (Anti-Slip) |

| 난연제 | Available (ASTM E84 Class 1 or 2) |

| 제조 공정 | Pultrusion, Molding, Hand Lay-Up, RTM |

| 자외선 차단 | Yes (for outdoor applications) |

| 전기 전도도 | 비전도성 |

Standard & Custom Dimensions

-

Dimensions vary based on application requirements.

-

Length, width, and thickness can be custom-made to meet specific project needs.

-

FRP Special-Shaped Parts include complex geometries such as curves, angles, hollows, and reinforced structures.

-

Can be designed for integration with other FRP components.

3. Key Advantages of FRP Special-Shaped Parts

✅ Custom Design & High Flexibility

-

Manufactured in complex shapes and structures that traditional materials cannot achieve.

-

Can be tailored for specific engineering, aesthetic, or performance needs.

✅ Corrosion & Chemical Resistance

-

Resistant to acids, alkalis, and moisture, making them ideal for marine, industrial, and chemical plant environments.

-

아니요 rust, rot, or degradation like steel or wood.

✅ Lightweight Yet High Strength

-

70% lighter than steel while maintaining excellent structural integrity.

-

Easier to transport and install, reducing overall labor and logistics costs.

✅ 방염 옵션

-

Available in fire-retardant versions (ASTM E84 Class 1 or 2).

-

Suitable for industries requiring high safety standards.

✅ Weather & UV Resistance

-

UV-stabilized resins ensure longevity in outdoor and harsh weather conditions.

-

Withstands high humidity, extreme temperatures, and direct sunlight.

✅ 전기 및 열 절연

-

Non-conductive, ensuring safety in electrical applications.

-

Low thermal conductivity, making it suitable for heat-sensitive environments.

✅ Low Maintenance & Long Service Life

-

Requires minimal maintenance compared to metal or wood.

-

Service life of 25+ years, reducing long-term replacement costs.

4. Applications of FRP Special-Shaped Parts

🔹 Industrial & Structural Applications

✔ Support structures, customized beams, enclosures, and mechanical housings.

✔ Non-metallic reinforcement for industrial equipment and machinery.

🔹 Marine & Offshore Industry

✔ Corrosion-resistant components for ships, docks, and offshore platforms.

✔ Boat hulls, custom deck structures, and safety enclosures.

🔹 Construction & Infrastructure

✔ Architectural facades, decorative panels, and lightweight construction elements.

✔ Reinforced bridges, railings, and walkway systems.

🔹 Automotive & Transportation

✔ Custom body panels, aerodynamic fairings, and lightweight vehicle components.

✔ Railway and metro system components for reduced weight and improved efficiency.

🔹 Chemical & Petrochemical Industry

✔ Custom tanks, pipelines, and storage solutions resistant to harsh chemicals.

✔ Non-corrosive enclosures for hazardous material storage.

🔹 Electrical & Telecommunications

✔ Non-conductive enclosures, junction boxes, and cable management systems.

✔ FRP antennas, radomes, and insulation components.

5. Comparison: FRP Special-Shaped Parts vs. Traditional Materials

| 특징 | FRP Special-Shaped Parts | 강철 | Aluminum | 목재 |

|---|---|---|---|---|

| 무게 | 경량 | Heavy | 보통의 | 경량 |

| 부식 저항 | 훌륭한 | Poor (Rusts) | 보통의 | Low (Rot & Mold) |

| Strength-to-Weight Ratio | 높은 | 높은 | Medium | 낮은 |

| 전기 전도도 | 비전도성 | Conductive | Conductive | 비전도성 |

| Weather Resistance | 훌륭한 | 가난한 | 보통의 | 가난한 |

| Maintenance | 낮은 | 높은 | 보통의 | 높은 |

| Custom Shape Capability | 훌륭한 | Limited | Limited | 보통의 |

6. How to Choose the Right FRP Special-Shaped Part?

Consider the following factors when selecting FRP Special-Shaped Parts:

✅ Application Type – Industrial, marine, construction, or transportation use.

✅ Resin Type – 폴리에스테르 (standard), 비닐 에스테르 (chemical-resistant), or Epoxy (high-strength).

✅ Size & Shape – Custom dimensions, angles, and reinforcement options.

✅ 표면 처리 – Smooth, gritted (anti-slip), or textured.

✅ Environmental Conditions – UV-resistant coatings for outdoor exposure.

✅ Fire Safety Compliance – Fire-retardant versions for safety-critical applications.

7. Frequently Asked Questions (FAQ)

Q1: What manufacturing processes are used for FRP Special-Shaped Parts?

FRP Special-Shaped Parts are produced using:

-

Pultrusion – For linear, strong profiles.

-

Molding & Hand Lay-Up – For complex shapes and large structures.

-

수지 전사 성형(RTM) – For high-precision, intricate designs.

Q2: Are FRP Special-Shaped Parts customizable?

Yes! They can be fully customized for shape, size, thickness, resin type, surface finish, and color.

Q3: How durable are FRP Special-Shaped Parts?

They have a service life of 25+ years, with resistance to impact, chemicals, and harsh weather.

Q4: Can FRP Special-Shaped Parts be used in high-temperature environments?

Yes, heat-resistant resins can be used to withstand extreme temperatures.

Q5: How do FRP Special-Shaped Parts compare to traditional materials like steel?

They are lighter, corrosion-resistant, easier to install, and require less maintenance than steel.

Q6: What industries benefit most from FRP Special-Shaped Parts?

Industries such as construction, marine, chemical, transportation, and infrastructure use FRP for lightweight, corrosion-resistant, and custom-designed components.

Q7: How are FRP Special-Shaped Parts installed?

They can be installed using mechanical fasteners, adhesives, or integrated assembly methods.

8. Conclusion

FRP Special-Shaped Parts offer unmatched design flexibility, strength, and durability ~을 위한 industrial, structural, and marine applications. Their lightweight, corrosion resistance, and long lifespan make them superior to traditional materials like steel, aluminum, and wood.

FRP Special-shaped Parts

시리즈 :

주요제품 >애플리케이션

🔹 Industrial Structures – Support frames, walkways, and platforms. 🔹 Marine & Offshore – Shipbuilding, docks, and oil rigs. 🔹 Chemical & Petrochemical – Acid-resistant structural components. 🔹 Electrical & Power – Non-conductive framing and cable support. 🔹 Water & Wastewater – Corrosion-resistant water treatment structures.

상표명 :

TF컴포지트

상품명 :

FRP Special-shaped Parts

재료 :

유리 섬유

색상 :

Gray,Other

자주하는 질문

질문 :

How long do FRP Special-Shaped Parts last?

ㅏ :

FRP Special-Shaped Parts have a service life of 25+ years, significantly outlasting many traditional materials such as wood (5-10 years) or steel (10-15 years, depending on conditions).

질문 :

Can FRP Special-Shaped Parts be used outdoors?

ㅏ :

Yes! FRP Special-Shaped Parts are highly UV-resistant and weatherproof, making them ideal for outdoor use in harsh environments like marine applications, chemical plants, and infrastructure.

질문 :

What are the typical dimensions and sizes of FRP Special-Shaped Parts?

ㅏ :

The dimensions of FRP Special-Shaped Parts vary greatly depending on the application and design. However, common sizes include: Length: Can be customized based on the project requirements (commonly 3m to 6m). Thickness: Typically 3mm to 50mm or more depending on strength needs. Width: Can be tailored based on the required shape and function (from small profiles to large sheets). Custom shapes such as curved, angled, and hollow profiles can be created to match exact design specifications.

기타 관련 제품