제품 성능 소개

Unlike conventional twisted yarns, untwisted rovings maintain their linear bundle structure throughout processing. This unique construction results in higher fabric strength, improved impregnation properties, and better dimensional stability. As an essential raw material for woven and stitched fabrics, untwisted roving is designed to deliver optimized weaving performance and high-quality composite properties.

2. Product Definition and Structure

Untwisted roving is a bundle of continuous glass filaments grouped together without twisting. Each roving consists of thousands of filaments (typically 2400, 4800, or 9600 tex), which are held together by a binding agent or sizing. The absence of twist allows the roving to lay flat, improving fabric uniformity and enhancing resin wet-out capabilities.

Key Characteristics:

-

연속 필라멘트 of E-glass, ECR-glass, or high-performance specialty glass

-

No twist – filaments remain parallel and flat

-

Custom tex values (e.g., 300, 600, 1200, 2400, 4800, 9600)

-

Silane-based sizing compatible with various resin systems (e.g., epoxy, polyester, vinyl ester)

-

Excellent weaving compatibility

3. Manufacturing Process

The production of untwisted roving involves several critical steps:

-

Glass Melting: High-purity raw materials (silica, alumina, boron oxide) are melted at temperatures exceeding 1400°C in a platinum-rhodium bushing.

-

Fiberization: The molten glass is extruded through small orifices in the bushing to form continuous filaments, typically 9–13 microns in diameter.

-

Sizing Application: A chemical sizing is sprayed onto the filaments immediately after extrusion. This sizing improves bundling, enhances resin compatibility, and minimizes fiber abrasion.

-

Gathering: The filaments are collected into a bundle (roving) using gathering shoes or combs, ensuring the fibers are aligned without twisting.

-

Winding: The untwisted roving is wound onto cylindrical packages or cheeses suitable for warping and weaving machines.

4. Applications

Untwisted roving is widely used across industries due to its superior performance characteristics. Major applications include:

4.1 Woven Roving Fabric

-

Used for structural reinforcement in hand lay-up and RTM processes

-

높은 강도 대 중량 비율

-

Common in boat hulls, tanks, and panels

4.2 Multiaxial Fabrics (Stitched or Non-Crimp)

-

Produced by combining rovings in multiple orientations (e.g., ±45°, 0°, 90°)

-

Enhanced mechanical properties

-

Popular in wind turbine blades, automotive body panels, and aerospace composites

4.3 Pultrusion and Filament Winding

-

While twisted roving is traditionally used, untwisted rovings may be used for flat profiles or wide reinforcements

4.4 Textile Industry

-

As warp and weft yarns for industrial textiles and fire-resistant fabrics

5. Advantages

Untwisted rovings offer numerous advantages over twisted rovings and conventional yarns:

| Advantage | 설명 |

|---|---|

| High Fabric Strength | Parallel alignment of fibers ensures better load distribution and increased tensile strength |

| Improved Impregnation | Reduced capillary resistance allows resins to penetrate evenly and quickly |

| Dimensional Stability | No twist means better fabric flatness and reduced yarn distortion |

| Process Efficiency | Suitable for high-speed weaving without excessive fiber breakage |

| Custom Compatibility | Tailored sizings ensure compatibility with a variety of resins and processes |

6. Types of Untwisted Roving

| 유형 | Tex (g/km) | Filament Diameter (μm) | Typical Use |

|---|---|---|---|

| E-glass 300 tex | 300 | 9 | Lightweight fabrics |

| E-glass 1200 tex | 1200 | 13 | Balanced woven roving |

| E-glass 2400 tex | 2400 | 13 | Heavy woven fabrics |

| ECR-glass 4800 tex | 4800 | 17 | Multiaxial fabrics |

| S-glass | Custom | Custom | High-performance aerospace fabrics |

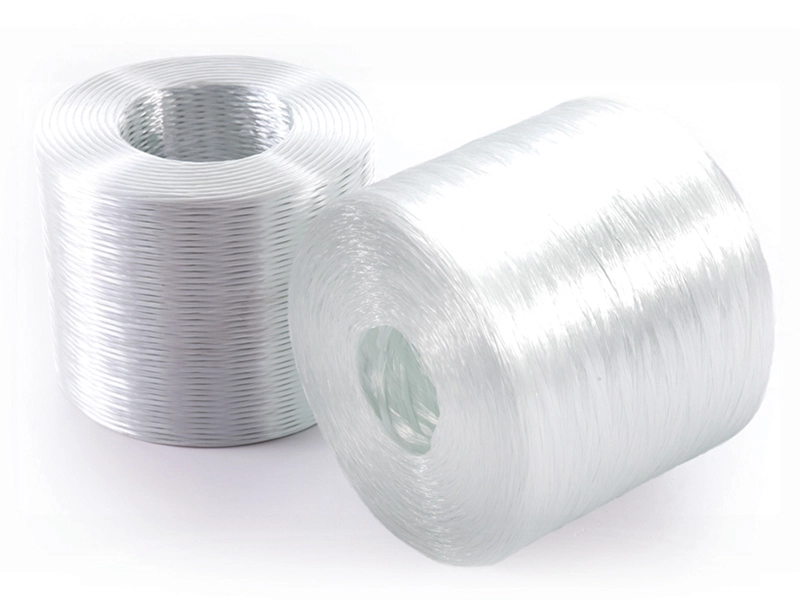

7. Packaging and Storage

7.1 Packaging

-

Roll/cheese weight: 15–25 kg (customizable)

-

Inner diameter: 76 mm or 152 mm

-

Outer diameter: up to 280 mm

-

Packaging type: Palletized or boxed, shrink-wrapped, and optionally nitrogen-purged

7.2 Storage Recommendations

-

Store in a cool, dry place away from direct sunlight and high humidity

-

Recommended temperature: 15–35°C

-

Relative humidity: ≤75%

-

Avoid stacking more than 3 pallets high

8. Technical Considerations in Weaving

The performance of untwisted roving in weaving is dependent on several factors:

-

Weaving Loom Compatibility: Must be suitable for warp insertion and tension control

-

Warp Strength: Rovings must resist tension and abrasion during weaving

-

Size Uniformity: Consistent roving diameter and tex are crucial for fabric quality

-

Weave Density: Higher tex values result in fewer yarns per square meter but increase fabric thickness

9. Technical Data Sheet (TDS)

Below is a sample TDS for a standard 2400 tex E-glass untwisted roving for weaving.

Technical Data Sheet

Product Name: Untwisted Roving for Weaving – 2400 tex

Glass Type: E-glass

제품 코드: UWR-E2400

Date: April 2025

1. General Properties

| 재산 | 단위 | 값 |

|---|---|---|

| Linear Density | tex | 2400 ± 5% |

| 필라멘트 직경 | µm | 13 ± 1 |

| Moisture Content | % | < 0.10 |

| Loss on Ignition (LOI) | % | 1.0 ± 0.2 |

| 인장강도 | N/텍스 | ≥ 0.30 |

| Sizing Type | – | Silane-based (multi-compatible) |

| 수지 호환성 | – | Polyester, Vinyl Ester, Epoxy |

| Yarn Twist | – | Zero (untwisted) |

2. Performance Parameters

| 모수 | 시험 방법 | Result |

|---|---|---|

| Bundle Integrity | ASTM D578 | 훌륭한 |

| Abrasion Resistance | Internal Method | 높은 |

| Weavability | Internal Test | 훌륭한 |

| Impregnation Rate | ASTM D3533 | ≤ 30 seconds |

| Tensile Modulus | ASTM D2343 | 73 GPa |

| Elongation at Break | ASTM D2343 | 4.8% |

3. Packaging

-

Form: Cylindrical cheese on paper core

-

Weight per roll: ~20 kg

-

Rolls per pallet: 48

-

Pallet size: 1150 × 1150 × 1000 mm

-

Gross weight per pallet: ~960 kg

4. Shelf Life

-

Recommended shelf life: 12 months from manufacturing date under controlled storage conditions.

10. Quality Assurance and Compliance

-

Standards Met:

-

ISO 9001: Quality Management System

-

ISO 14001: Environmental Management System

-

REACH and RoHS compliant

-

OEKO-TEX or fire-resistance certifications (upon request)

-

-

In-Process Controls:

-

Online tex monitoring

-

Tension consistency checks

-

Sizing distribution uniformity

-

-

Final Inspection:

-

Tex, moisture, and LOI analysis

-

Surface inspection

-

Yarn break test

-

11. Environmental Impact and Recycling

Untwisted roving made from E-glass and ECR-glass is considered non-toxic and inert. However, manufacturers are encouraged to:

-

Use water-based sizings to reduce VOC emissions.

-

Implement closed-loop recycling systems for offcuts and fabric waste.

-

Promote lightweighting in composites to reduce the carbon footprint in end-use applications (e.g., automotive and wind energy).

12. Conclusion

Untwisted roving for weaving is a cornerstone material for producing high-performance fiberglass fabrics and composites. With its outstanding mechanical properties, ease of processing, and compatibility with modern resin systems, it plays a vital role in lightweight structural applications. Whether used in multiaxial fabrics for wind blades or in woven roving for boat hulls, untwisted roving ensures performance, durability, and processing efficiency.

For manufacturers seeking to improve composite strength, reduce process times, and maintain high product consistency, untwisted roving is a proven and indispensable solution.

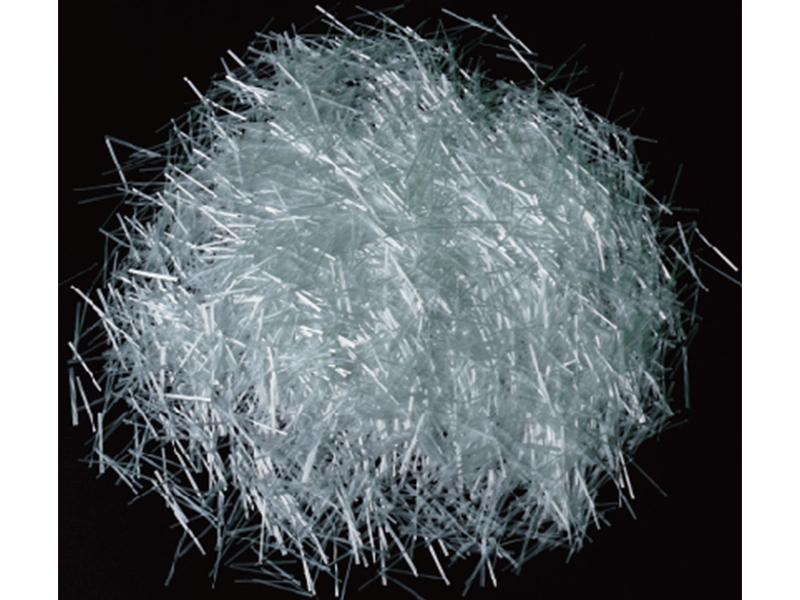

Untwisted roving for preforms

시리즈 :

유리 섬유 조립 로빙 >애플리케이션

자동차 / 소비재 및 업무용 장비 / 스포츠 및 레저 / 전기전자 / 건축 및 건설 / 인프라

유리 종류 :

이자형

상품명 :

Untwisted roving for preforms

자주하는 질문

질문 :

공장이세요? 당신은 어디 어디에 있습니까?

ㅏ :

우리는 FRP 격자 및 인발 성형 프로파일 제조업체, FRP 원사 재료 상인입니다. 우리는 중국 Jushi Co.의 최대 유통업체입니다. 또한 여러 FRP 원사 제조업체의 제품을 판매합니다. 우리는 중국 안후이에 있습니다.

질문 :

문의 시 어떤 정보를 추천하시나요?

ㅏ :

1. 어떤 텍스트가 필요합니까? 2. 어떤 용도로 사용하시나요? 아니면 기술이 직조, 인발 또는 와인딩입니까? 3. 수량은 얼마나 필요합니까? 4. 어떤 레진을 조합하나요? 폴리에스터 수지인가, 에폭시 수지인가? 5. FOB 또는 CIF 가격이 필요합니까? CIF인 경우 포트를 알려주십시오.

질문 :

MOQ는 무엇입니까?

ㅏ :

보통 1톤

질문 :

패키지 및 배송

ㅏ :

일반 패키지: 판지(단위 가격에 포함됨) 특수 패키지: 실제 상황에 따라 충전해야 합니다. 일반 배송: 귀하가 지정한 화물 운송.

질문 :

언제 제안할 수 있습니까?

ㅏ :

우리는 일반적으로 귀하의 문의를 받은 후 24시간 이내에 인용합니다. 당신이 가격을 얻기 위해 매우 긴급한 경우 pls는 저희에게 전화하거나 귀하의 이메일로 알려주십시오. 그래야 우리가 당신에게 우선 순위를 회신할 수 있습니다.

질문 :

샘플 비용은 어떻게 청구하나요?

ㅏ :

당사 재고에서 샘플이 필요한 경우 무료로 제공할 수 있지만 운임을 지불해야 합니다. 특별한 크기가 필요한 경우 주문할 때 환불 가능한 샘플 제작 수수료를 청구합니다.

질문 :

생산을 위한 당신의 배달 시간은 무엇입니까?

ㅏ :

재고가 있는 경우 7일 이내에 배송할 수 있습니다. 재고가 없는 경우 7~15일 소요됩니다!

기타 관련 제품