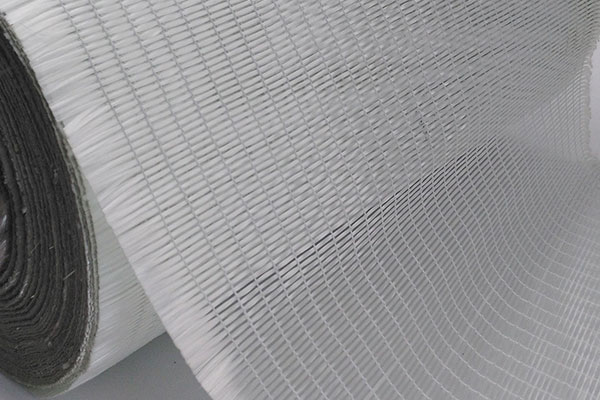

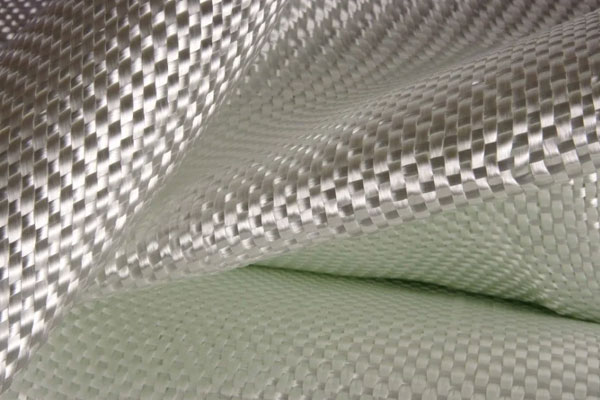

Glass fiber stitched fabric is a composite reinforcement material made from continuous glass fibers that are stitched together to form a fabric with a specific structure. Unlike traditional woven fabrics, which have fibers interlaced in a crisscross pattern, stitched fabric is created by stitching together layers of fibras de vidro that run in specific directions. This design provides enhanced strength, stiffness, e flexibility in composite applications.

Introdução ao desempenho do produto

The stitching process not only holds the fibers together but also helps to distribute stresses more evenly across the fabric. As a result, stitched glass fiber fabrics offer superior mechanical properties compared to some other types of reinforcement fabrics. This fabric is commonly used in composite manufacturing, especially in industries such as aerospace, automotivo, marine, e construction.

Glass fiber stitched fabric is known for its high tensile strength, low weight, e excellent corrosion resistance. It is especially useful when combined with resinas (such as epoxy or polyester) to create strong, durable composite materials that can withstand high stresses, temperatures, and harsh environments.

General Product Parameters:

-

Material: Typically made from E-glass (electrical glass) or S-glass (strengthened glass), with the fibers oriented in specific directions depending on the stitching pattern.

-

Peso: The weight of stitched glass fiber fabric typically ranges from 150 gsm to 800 gsm, depending on the application requirements. Heavier fabrics are used in applications requiring high strength.

-

Grossura: Varies based on the weight and number of layers; typically ranges from 0.2 mm to 0.8 mm.

-

Stitching pattern: Can be multi-directional (typically 0°, 90°, or even ±45°) or unidirectional based on the intended application and the stresses the material will experience.

-

Largura: Common widths range from 100 mm to 1000 mm, though custom widths can be produced for specific requirements.

-

Compatibilidade de resina: Compatible with a variety of resins, such as epóxi, poliéster, vinyl ester, e phenolic resins.

-

Resistência à tracção: Typically in the range of 3000 MPa to 4500 MPa (depending on the glass type and fabric weight).

-

Alongamento: Usually in the range of 2% to 5% depending on the fiber type and treatment.

-

Resistência térmica: Can withstand temperatures up to 550°C, depending on the resin used in conjunction with the fabric.

-

Moisture Absorption: Very low moisture absorption, making it ideal for applications exposed to wet or humid conditions (e.g., marine or chemical industries).

-

Cor: Most commonly white or light grey, though other colors may be possible depending on the resin or finishing process used.

Formulários:

-

Aeroespacial: Used in lightweight composite structures such as wings, fuselage parts, and interior components.

-

Automotivo: Stitched glass fiber fabrics are used in body panels, reinforced chassis, and other structural components in the automotive industry.

-

Marinho: Ideal for use in boat hulls, decks, and other marine structures where strength and resistance to water and corrosion are critical.

-

Wind Energy: Used in the construction of wind turbine blades, where high strength and low weight are essential.

-

Equipamentos esportivos: Used to reinforce equipment like bicycle frames, ski poles, e snowboards.

-

Construção: Employed for reinforcing concrete structures or other composite building materials.

Benefits of Glass Fiber Stitched Fabric:

-

High Mechanical Strength: Stitched fabric offers excellent strength in both the warp (lengthwise) and weft (widthwise) directions, which makes it ideal for load-bearing applications.

-

Flexibilidade: Stitched glass fiber fabric is more flexible than woven glass fabrics, allowing it to conform to curved surfaces and complex geometries.

-

Reduced Delamination: The stitching process helps to prevent delamination in composite materials, improving long-term durability and performance.

-

Increased Impact Resistance: The multi-layered stitching provides additional impact resistance, making the material more durable in applications prone to mechanical shock or abrasion.

-

Low Moisture Absorption: Glass fiber is inherently resistant to moisture, which makes it suitable for applications in marine, marine, ou outdoor environments.

-

Easy Handling: Stitched glass fiber fabric is easier to handle compared to woven fabrics because of its flexibility, making it ideal for complex shapes and intricate lay-up processes.

Glass Fiber Stitched Fabric

Series :

Glass Fiber Fabric >aplicativo

Aerospace: Used in lightweight composite structures such as wings, fuselage parts, and interior components. Automotive: Stitched glass fiber fabrics are used in body panels, reinforced chassis, and other structural components in the automotive industry. Marine: Ideal for use in boat hulls, decks, and other marine structures where strength and resistance to water and corrosion are critical. Wind Energy: Used in the construction of wind turbine blades, where high strength and low weight are essential. Sports Equipment: Used to reinforce equipment like bicycle frames, ski poles, and snowboards. Construction: Employed for reinforcing concrete structures or other composite building materials.

Marca :

TFcomposite

Nome do Produto :

Glass Fiber Stitched Fabric

Perguntas frequentes

P:

What is the difference between stitched fabric and woven fabric?

A :

Stitched Fabric: Fibers are stitched together in specific directions, offering superior strength and stiffness, particularly in multi-directional applications. Woven Fabric: Fibers are interlaced in a crisscross pattern, which can result in more uniform properties in all directions but may not offer the same directional strength as stitched fabric.

P:

Can glass fiber stitched fabric be used for outdoor applications?

A :

Yes, glass fiber stitched fabric is highly resistant to moisture and UV degradation, making it ideal for outdoor applications. It is widely used in marine environments for boat hulls and outdoor structures, where long-term exposure to the elements is common.

P:

How do I apply glass fiber stitched fabric in a composite lay-up?

A :

Prepare the mold by ensuring it is clean and ready for resin application. Cut the fabric to the required size and shape, ensuring it fits the mold or surface you are working with. Apply resin: Saturate the fabric with resin, using a roller or brush to ensure full wetting. Layer the fabric: If additional layers are needed, add them with proper orientation, ensuring the stitching aligns appropriately. Cure the composite material according to the resin's specifications (usually in an oven or at room temperature).

P:

What are the main advantages of using glass fiber stitched fabric in composite materials?

A :

The primary benefits include: Increased strength and impact resistance. Flexibility for complex shapes and curvatures. Reduced delamination due to the stitching pattern. Moisture and heat resistance, which is ideal for marine and industrial environments. High durability under mechanical stresses and harsh conditions.

P:

What are the temperature and chemical resistance properties of stitched glass fiber fabric?

A :

Stitched glass fiber fabric is resistant to temperatures up to 550°C depending on the type of resin used. It is also highly resistant to a range of chemicals, including acids, alkalis, and oils, making it suitable for chemical-resistant applications and environments where the material may be exposed to harsh substances.

Outros produtos relacionados