Bisphenol A Epoxy Resin (commonly abbreviated as DGEBA, ou Diglycidyl Ether of Bisphenol A) is one of the most widely used and versatile thermosetting resins in the composites, adhesives, coatings, and electronics industries. It is a reaction product of bisphenol A e epichlorohydrin, forming a liquid or solid polymer structure with excellent chemical, thermal, mechanical, and electrical properties.

Introdução ao desempenho do produto

These epoxy resins are primarily used for high-performance coatings, electrical insulation, fiber-reinforced composites, casting materials, adhesives, e encapsulation compounds.

2. Chemical Structure and Composition

The chemical structure of Bisphenol A epoxy resin is defined by:

-

Base structure: Diglycidyl ether of bisphenol A (DGEBA)

-

Molecular Formula: C21H24O4

-

CAS Number: 25068-38-6

-

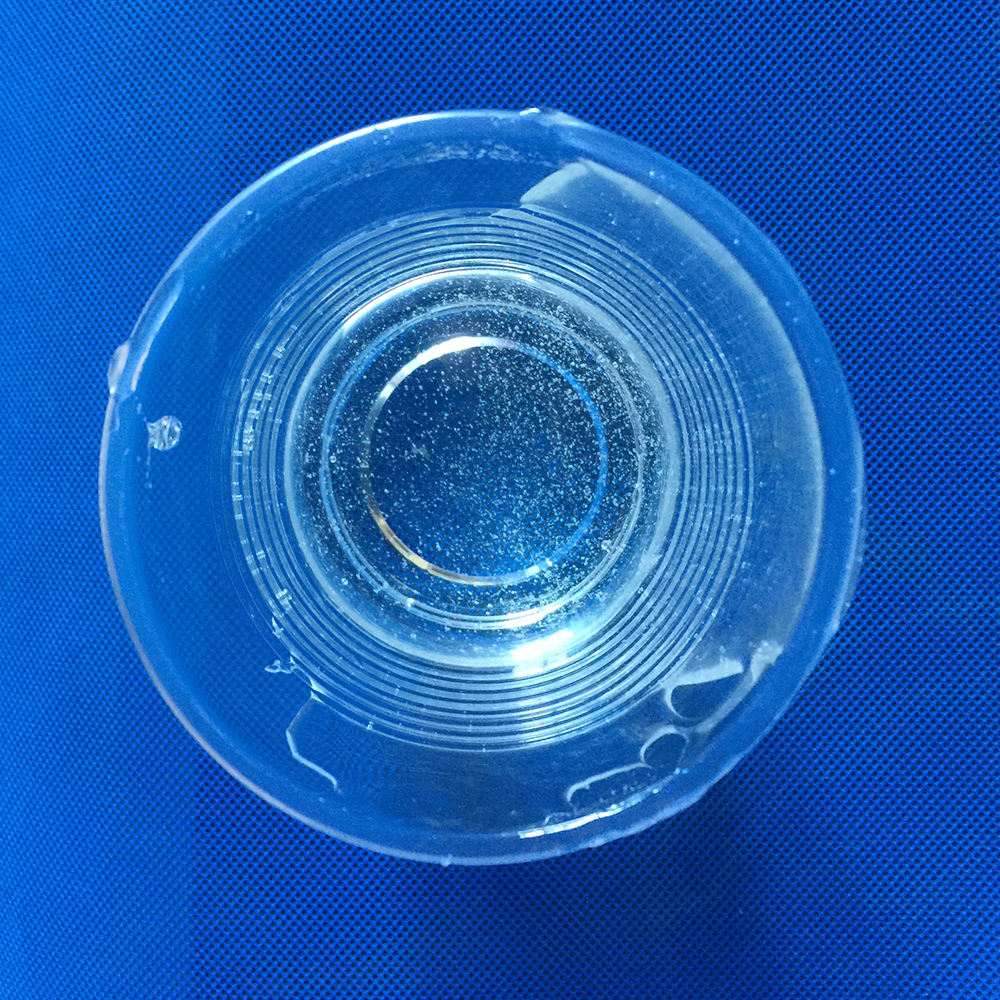

Appearance: Typically clear, colorless to light yellow viscous liquid (for low molecular weight grades) or solid (for high molecular weight grades)

General Reaction:

Bisphenol A + Epichlorohydrin → Bisphenol A Diglycidyl Ether (via condensation and dehydrohalogenation)

3. Key Features and Benefits

-

Excellent Adhesion: Strong bonding to a variety of substrates, including metals, glass, wood, and plastics.

-

Resistência química: Strong resistance to acids, alkalis, and solvents.

-

Electrical Insulation: Superior dielectric strength and low conductivity.

-

Mechanical Strength: High flexural, tensile, and compressive strength.

-

Dimensional Stability: Low shrinkage during cure, good moisture resistance.

-

Resistência térmica: Stable at elevated temperatures (up to 130–150°C).

-

Versatility: Can be formulated with a wide range of curing agents for various applications.

4. Applications

a. Coatings

Used in protective coatings for:

-

Marine and offshore structures

-

Industrial floors

-

Pipes and tanks

-

Automotive refinishing

b. Adhesives

Ideal for bonding:

-

Metals

-

Ceramics

-

Composites

-

Glass and wood

c. Electrical and Electronics

-

Potting and encapsulation of circuit boards

-

Transformers and insulators

-

PCB laminates

d. Composites

Used as a matrix resin for:

-

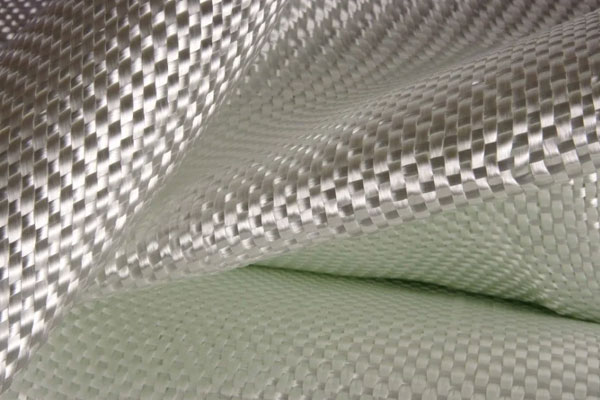

Carbon fiber-reinforced composites

-

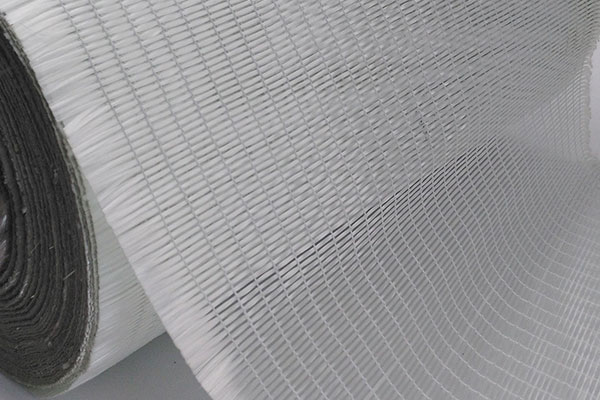

Glass-reinforced components

-

Aerospace and automotive parts

e. Construction Materials

-

Grouts and mortars

-

Anchoring systems

-

Crack repair

5. Grades of Bisphenol A Epoxy Resin

Bisphenol A epoxy resins are typically categorized by:

-

Molecular weight: Low to high

-

Viscosidade: Liquid (100–15000 mPa·s) or solid (flakes or powder)

-

Functionality: Mono, di, or multifunctional

-

Modification: Reactive diluents, flexibilizers, brominated (flame-retardant) versions

Common Grades:

-

Liquid Epoxy Resin (Standard DGEBA) – Used in coatings, adhesives, laminates.

-

Solid Epoxy Resin (High Molecular Weight) – Used in powder coatings, electrical insulation.

-

Brominated Epoxy Resin – Flame retardant.

-

Flexible Epoxy Resins – With improved elongation and impact resistance.

6. Technical Data Sheet (TDS)

Below is a typical TDS for Liquid Bisphenol A Epoxy Resin (Standard Grade):

| Propriedade | Método de teste | Typical Value |

|---|---|---|

| Appearance | Visual | Clear to light yellow liquid |

| Epoxy Equivalent Weight (EEW) | ASTM D1652 | 185–192 g/eq |

| Viscosity @ 25°C | ASTM D445 | 11,000 – 14,000 mPa·s |

| Color (Gardner) | ASTM D1544 | ≤ 1 |

| Specific Gravity @ 25°C | ASTM D1475 | 1.16 – 1.18 |

| Flash Point | ASTM D93 | > 250°C (closed cup) |

| Hydrolyzable Chlorine | IEC 584 | < 0.5% |

| Shelf Life | - | 12 months @ 25°C |

7. Curing and Hardeners

Bisphenol A epoxy resin cures through the reaction with hardeners such as:

-

Amine-based (aliphatic, cycloaliphatic, aromatic)

-

Anhydrides

-

Phenolic resins

-

Polyamides

Curing Conditions:

-

Room temperature or elevated temperature

-

Exothermic reaction; higher temperatures accelerate curing

Example Cure System:

-

Resina: DGEBA

-

Endurecedor: Polyamine (2:1 stoichiometric ratio)

-

Cure Time: 24 hrs @ 25°C or 2 hrs @ 60°C

8. Performance Properties After Cure

| Propriedade | Método de teste | Typical Value |

|---|---|---|

| Resistência à tracção | ASTM D638 | 70 – 85 MPa |

| Resistência à flexão | ASTM D790 | 110 – 130 MPa |

| Resistência à compressão | ASTM D695 | 110 – 140 MPa |

| Temperatura de deflexão de calor (HDT) | ASTM D648 | 115 – 135°C |

| Glass Transition Temperature (Tg) | DSC | 120 – 140°C |

| Water Absorption (24 hrs) | ASTM D570 | < 0.1% |

| Dielectric Strength | ASTM D149 | > 18 kV/mm |

9. Handling and Storage

-

Store in original containers tightly sealed, under dry and cool conditions.

-

Avoid contact with skin and eyes.

-

Use personal protective equipment (gloves, goggles, respirators).

-

Use within shelf life for optimal performance.

10. Environmental and Regulatory Considerations

-

REACH compliant – Subject to registration under European chemicals regulation.

-

RoHS compliant – Free from lead, mercury, and other restricted substances.

-

Low VOC content – Especially in solvent-free systems.

Disposal:

-

As per local hazardous waste regulations.

-

Resin and hardener must not be mixed in uncontrolled conditions.

11. Advantages vs. Other Resins

| Resin Type | Strengths |

|---|---|

| Bisphenol A Epoxy | Excellent balance of cost, performance, and versatility |

| Phenolic Resins | High thermal resistance, but brittle and harder to process |

| Polyester Resins | Cheaper, faster cure, but lower mechanical/thermal performance |

| Vinyl Ester Resins | Better chemical resistance, more expensive |

| Polyurethane Resins | High flexibility, lower chemical resistance |

12. Limitations

-

Moderate UV resistance (may require stabilizers or coatings)

-

Brittleness in highly cross-linked systems (may need flexibilizers)

-

Moisture sensitivity during curing (affects mechanical properties)

-

Requires careful stoichiometry and temperature control during curing

13. Customization and Modifications

Bisphenol A resins can be modified with:

-

Reactive diluents (to lower viscosity)

-

Toughening agents (rubber particles, polyurethanes)

-

Fillers and pigments

-

Thixotropic agents

These enhance processability and tailor mechanical or thermal characteristics for specific applications.

14. Conclusion

Bisphenol A Epoxy Resin is a foundational material in advanced composites, coatings, adhesives, and electronics due to its outstanding performance and adaptability. With a wide range of grades, cure systems, and modification options, it is a go-to material for engineers and formulators seeking durability, chemical resistance, and strong bonding properties.

Bisphenol A Epoxy Resin

Series :

Produtos proxy >aplicativo

revestimentos, adesivos e compósitos

Nome do Produto :

o-phthalic resin

Perguntas frequentes

P:

What is Bisphenol A Epoxy Resin and how is it made?

A :

Bisphenol A Epoxy Resin, often abbreviated as DGEBA (Diglycidyl Ether of Bisphenol A), is a type of epoxy resin produced through the reaction of bisphenol A with epichlorohydrin. This reaction results in a highly reactive thermosetting polymer that contains epoxy groups capable of forming strong cross-linked structures when cured. It is widely used in adhesives, coatings, electrical insulation, composites, and construction applications.

P:

What are the key advantages of using Bisphenol A Epoxy Resin over other resins?

A :

Bisphenol A epoxy resins are popular due to their: Excellent mechanical strength and adhesion properties Good chemical resistance to water, acids, and solvents Outstanding electrical insulation, making them ideal for electronics Dimensional stability and low shrinkage after curing Customizability, with flexibility to alter viscosity, toughness, and cure speeds through various formulations

P:

Is Bisphenol A Epoxy Resin safe to use, and what precautions should be taken?

A :

Bisphenol A epoxy resins are safe to use when handled properly. However, before curing, the uncured resin may cause: Skin irritation or allergic reactions Eye irritation Harm if inhaled in vapor form Precautions include: Wearing gloves, safety goggles, and appropriate clothing Ensuring good ventilation in the workspace Avoiding direct skin contact Storing the resin in tightly sealed containers away from heat and moisture Once fully cured, the resin is considered inert and non-toxic under most conditions.

Outros produtos relacionados