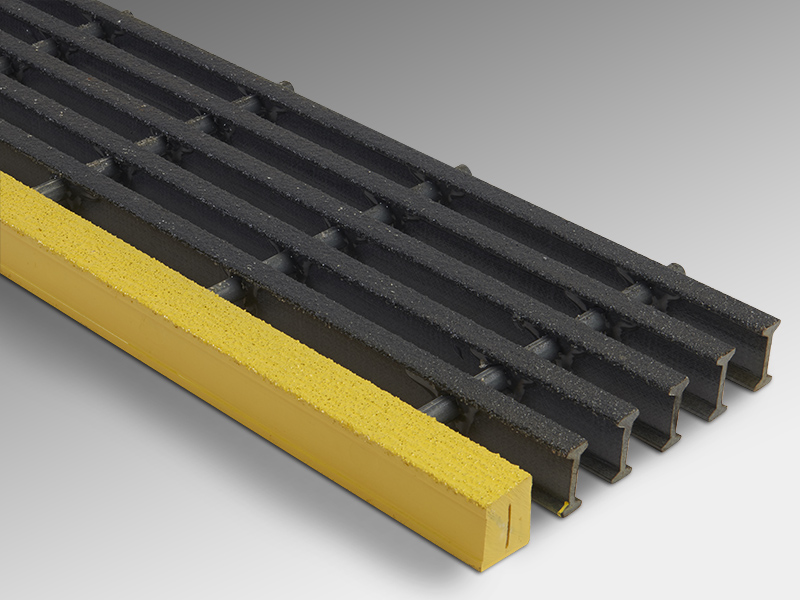

Fiberglass stair treads and stair covers are an essential complement to molded and pultruded grating installations.

Introdução ao desempenho do produto

Fiberglass stair treads are essential components in industrial, commercial, and even residential environments where durability, safety, and resistance to environmental factors are critical. Made from fiberglass-reinforced plastic (FRP), these treads offer exceptional performance and are increasingly popular as an alternative to traditional materials like wood, steel, or aluminum. Below is an in-depth exploration of fiberglass stair treads, covering their materials, types, benefits, applications, installation, maintenance, and future trends.

1. What Are Fiberglass Stair Treads?

Fiberglass stair treads are flat steps constructed from FRP composite materials. These treads are designed for use in stairs, walkways, or platforms and are particularly valued for their strength, slip resistance, and ability to withstand harsh environments.

Key Characteristics

- Resistência à corrosão: FRP treads resist damage from chemicals, moisture, and extreme weather.

- Superfície antiderrapante: Often embedded with gritted coatings to enhance safety.

- Lightweight but Strong: Easy to handle yet capable of supporting substantial weight.

2. Composition and Manufacturing of Fiberglass Stair Treads

Materials

Fiberglass stair treads consist of the following components:

- Fibers: Glass fibers provide structural strength and rigidity.

- Resinas:

- Polyester Resins: Cost-effective and suitable for moderate environments.

- Vinyl Ester Resins: Higher chemical resistance, used in corrosive settings.

- Epoxy Resins: Maximum strength and resistance, though more expensive.

- Fillers and Additives:

- UV stabilizers, fire retardants, and pigments enhance performance and longevity.

Manufacturing Processes

- Pultrusion:

- Continuous glass fibers are saturated in resin and pulled through a heated die to create uniform panels.

- Ideal for producing structural components like grating used in treads.

- Moldagem:

- Fiberglass mats are placed in a mold and infused with resin to create custom shapes or specific designs.

- Suitable for unique or non-standard stair tread configurations.

3. Types of Fiberglass Stair Treads

Fiberglass stair treads are available in various designs to suit specific requirements:

3.1. Molded Stair Treads

- Made from molded FRP grating.

- Provides high strength and slip resistance.

- Suitable for heavy-duty industrial environments.

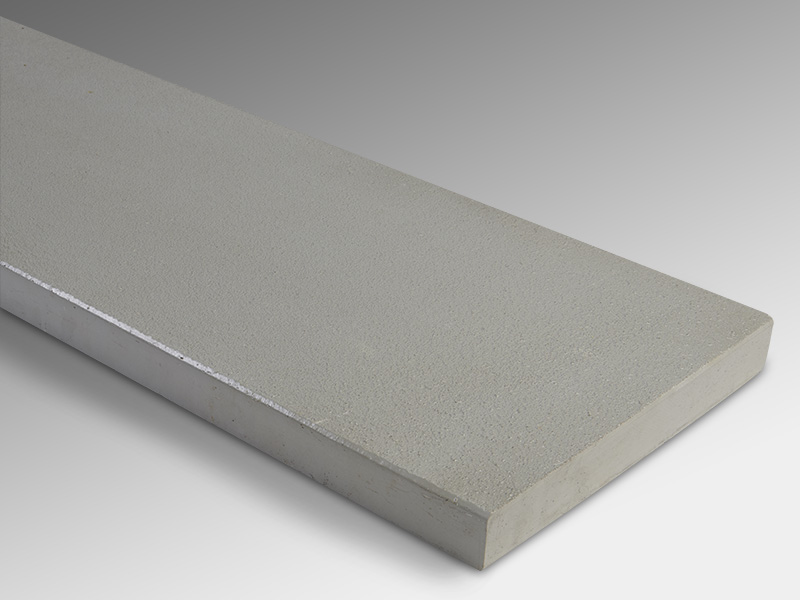

3.2. Pultruded Stair Treads

- Made from pultruded FRP panels with consistent structural properties.

- Lightweight and ideal for areas requiring precise dimensions.

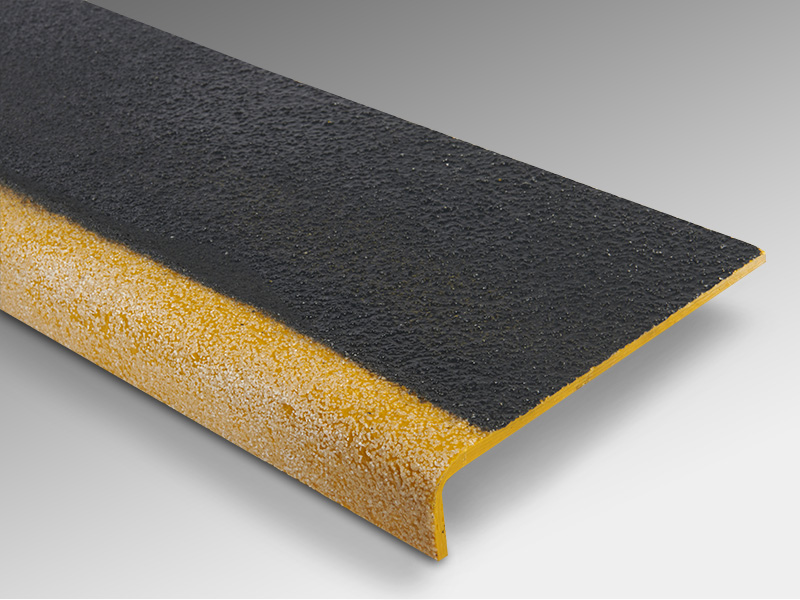

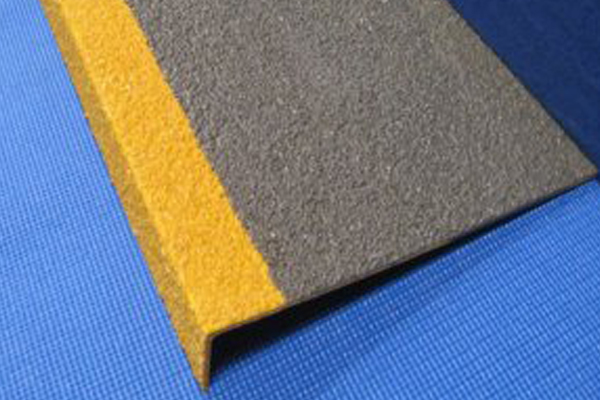

3.3. Covered Stair Treads

- Feature a non-slip surface layer, often with an embedded grit coating.

- Suitable for environments requiring enhanced traction, such as wet or oily conditions.

3.4. Customized Stair Treads

- Tailored designs for specific applications.

- Includes options for additional safety features, such as contrasting nosing or glow-in-the-dark strips.

4. Key Benefits of Fiberglass Stair Treads

Fiberglass stair treads offer numerous advantages over traditional materials:

4.1. Durability

- Resistant to corrosion, rust, and rot, even in harsh environments.

- Long lifespan with minimal degradation.

4.2. Slip Resistance

- Gritted or textured surfaces provide excellent traction.

- Ensures safety in wet, oily, or icy conditions.

4.3. Lightweight

- Easy to transport, handle, and install.

- Reduces structural loads on staircases.

4.4. Low Maintenance

- Requires no painting or sealing.

- Easily cleaned with water or mild detergents.

4.5. Chemical and Environmental Resistance

- Withstands exposure to acids, alkalis, and other corrosive substances.

- Ideal for marine or industrial environments.

4.6. Non-Conductive

- Electrically and thermally non-conductive, enhancing safety in high-voltage areas.

4.7. Fire Resistance

- Fire-retardant options available for added safety in critical areas.

4.8. Cost-Effective

- Lower lifetime costs compared to steel or aluminum due to minimal maintenance and extended service life.

5. Applications of Fiberglass Stair Treads

Fiberglass stair treads are versatile and widely used across different sectors:

5.1. Industrial Facilities

- Chemical plants, oil refineries, and manufacturing facilities where exposure to corrosive substances is common.

5.2. Water and Wastewater Treatment Plants

- Resistant to moisture, chlorine, and chemical agents.

- Used on access platforms, walkways, and staircases.

5.3. Marine and Offshore Platforms

- Saltwater-resistant properties make them suitable for ships, docks, and coastal structures.

5.4. Commercial Buildings

- Public staircases, fire escapes, and maintenance platforms benefit from their slip-resistant and low-maintenance properties.

5.5. Residential Applications

- Outdoor stairs and decks that require weatherproof, non-slip solutions.

5.6. Public Infrastructure

- Parks, bridges, and urban walkways where durability and safety are priorities.

6. Design Standards and Compliance

Fiberglass stair treads are manufactured to meet industry standards and ensure safety:

- OSHA (Occupational Safety and Health Administration):

- Specifies tread width, depth, and slip resistance for workplace safety.

- ASTM (American Society for Testing and Materials):

- Provides guidelines for strength, durability, and fire resistance.

- ADA (Americans with Disabilities Act):

- Mandates features like contrasting nosing for accessibility.

- ISO Standards:

- Ensures international compliance with quality and performance metrics.

7. Installation of Fiberglass Stair Treads

Installing FRP stair treads is straightforward due to their lightweight and modular design. Below are the steps for successful installation:

7.1. Preparation

- Measure the stair dimensions and ensure surfaces are clean and level.

- Select the appropriate type and size of treads based on load requirements and environmental conditions.

7.2. Fitting

- Secure the stair treads onto the existing framework using stainless steel bolts, clips, or adhesives.

- Use pre-drilled holes or fittings provided by the manufacturer.

7.3. Alignment

- Ensure treads are properly aligned and spaced for consistent appearance and safety.

- Install contrasting nosing for enhanced visibility if required.

7.4. Safety Testing

- Conduct load tests and inspect connections for stability and compliance with safety standards.

8. Maintenance of Fiberglass Stair Treads

FRP stair treads require minimal maintenance but should be inspected periodically:

8.1. Cleaning

- Wash with water and mild soap to remove dirt, grease, and debris.

- Avoid abrasive cleaning agents that could damage the surface.

8.2. Inspection

- Check for any cracks, chips, or loose fasteners.

- Inspect grit coatings for wear and replace if necessary.

8.3. Repairs

- Damaged sections can often be replaced individually without dismantling the entire system.

- Use manufacturer-recommended adhesives and tools for repairs.

9. Customization Options

Fiberglass stair treads can be tailored to meet specific needs:

- Colors: Yellow, grey, green, or custom colors for branding or safety coding.

- Grit Types: Fine grit for light-duty areas; coarse grit for heavy-duty environments.

- Sizes and Shapes: Adjustable lengths, widths, and profiles for unique staircase designs.

- Características adicionais:

- Glow-in-the-dark strips for low-light environments.

- Anti-bacterial coatings for hygiene-sensitive areas.

10. Cost Considerations

While the initial investment in FRP stair treads may be higher than traditional materials, their long-term savings make them cost-effective. Key factors influencing costs include:

- Resin type (polyester is cheaper than vinyl ester or epoxy).

- Size and design complexity.

- Additional features like grit coatings or custom colors.

- Installation complexity.

11. Comparison: Fiberglass vs. Traditional Stair Treads

| Recurso | Fiberglass Stair Treads | Steel Stair Treads | Aluminum Stair Treads | Wooden Stair Treads |

|---|---|---|---|---|

| Resistência à corrosão | Excelente | Pobre | Moderado | Pobre |

| Anti-derrapante | Alto | Moderado | Moderado | Baixo |

| Peso | Leve | Heavy | Leve | Moderado |

| Maintenance | Baixo | Alto | Moderado | Alto |

| Lifespan | Long | Long | Moderado | Short |

| Cost (Initial) | Moderate to High | Low to Moderate | Alto | Baixo |

| Cost (Lifetime) | Baixo | Alto | Moderado | Alto |

12. Future Trends in Fiberglass Stair Treads

- Sustentabilidade: Increased use of recycled materials and eco-friendly resins.

- Smart Features: Integration of IoT sensors for monitoring tread conditions.

- Enhanced Durability: Development of new resins and coatings for extreme environments.

- Aesthetic Innovations: Custom patterns and finishes for architectural applications.

Conclusão

Fiberglass stair treads are a superior choice for environments demanding durability, safety, and resistance to harsh conditions. Their versatility, ease of installation, and low maintenance make them ideal for industrial, commercial, and residential applications.

Fiberglass Stair Treads

Series :

Fiberglass Stair Treads >aplicativo

Perguntas frequentes

Outros produtos relacionados