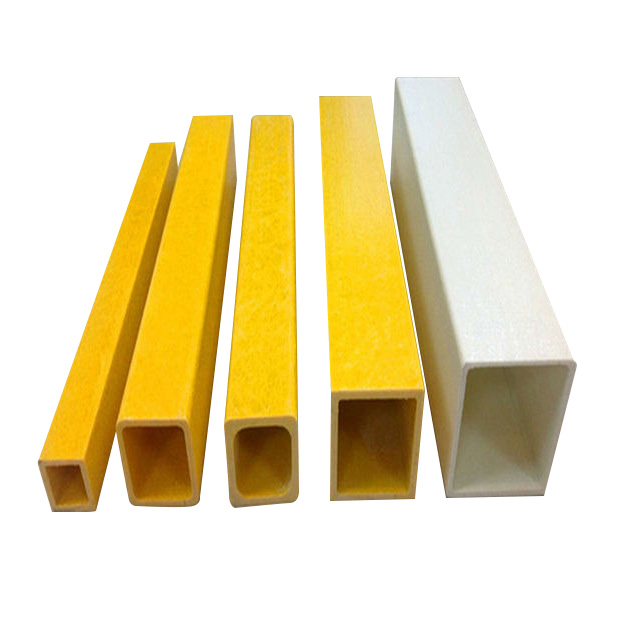

Fiber Reinforced Polymer (FRP) square tubes are a versatile and durable alternative to traditional materials like steel, aluminum, and wood. These profiles are widely used in various industries due to their exceptional strength, corrosion resistance, and lightweight properties. Manufactured through a high-precision pultrusion process, FRP square tubes are ideal for structural applications in construction, marine, chemical, electrical, and other industries where durability and performance are critical.

Introdução ao desempenho do produto

Processo de fabricação

FRP square tubes are produced using the pultrusion process, which ensures uniformity and high mechanical performance. The process involves pulling continuous strands of fiberglass through a resin bath and then shaping them in a heated die. This results in a consistent, high-quality composite material with superior strength and durability. Various resin systems, including polyester, vinyl ester, and epoxy, can be used to enhance properties like fire resistance, UV resistance, and chemical resistance.

Key Features and Advantages

-

Alta relação resistência/peso - Lighter than metals while maintaining excellent structural integrity.

-

Resistência à corrosão - Withstands exposure to moisture, chemicals, and extreme weather conditions.

-

Electrical Insulation - Non-conductive properties make them suitable for electrical applications.

-

Baixa manutenção - Requires minimal upkeep compared to traditional materials.

-

Opções de retardantes de fogo - Available with fire-resistant resins to meet stringent safety regulations.

-

Resistência UV - Designed to withstand prolonged exposure to sunlight without degradation.

-

Resistência química - Suitable for use in aggressive chemical environments.

-

Ease of Fabrication - Can be easily cut, drilled, and assembled using standard tools.

Specifications and Models

FRP square tubes come in a range of dimensions and wall thicknesses to suit different applications. Below are some standard sizes:

| Modelo | Outer Dimension (mm) | Wall Thickness (mm) | Length (m) |

|---|---|---|---|

| FRP-ST-25x25 | 25 x 25 | 3 | 3 - 12 |

| FRP-ST-30x30 | 30 x 30 | 3.5 | 3 - 12 |

| FRP-ST-40x40 | 40 x 40 | 4 | 3 - 12 |

| FRP-ST-50x50 | 50 x 50 | 5 | 3 - 12 |

| FRP-ST-60x60 | 60 x 60 | 5 | 3 - 12 |

| FRP-ST-75x75 | 75 x 75 | 6 | 3 - 12 |

| FRP-ST-100x100 | 100 x 100 | 8 | 3 - 12 |

| FRP-ST-120x120 | 120 x 120 | 10 | 3 - 12 |

| FRP-ST-150x150 | 150 x 150 | 12 | 3 - 12 |

| FRP-ST-200x200 | 200 x 200 | 15 | 3 - 12 |

Costumização: Custom sizes, wall thicknesses, and lengths can be manufactured based on project requirements.

Formulários

-

Construção e Infraestrutura - Used for structural supports, walkways, guardrails, and bridges.

-

Marítimo e Offshore - Ideal for docks, piers, and platforms due to its corrosion resistance.

-

Chemical Processing Plants - Resistant to harsh chemicals, making it suitable for industrial environments.

-

Electrical Industry - Non-conductive properties make them perfect for insulation, ladders, and cable supports.

-

Transporte - Used in lightweight structural components for vehicles, trains, and aircraft.

-

Esportes e Recreação - Utilized in sports equipment, stadium seating, and outdoor structures.

-

Agricultural Industry - Ideal for greenhouse frames, irrigation systems, and fencing.

Quality Standards and Certifications

FRP square tubes conform to international quality standards such as:

-

ISO 9001: Quality Management System

-

ASTM D638: Tensile Properties of Plastics

-

ASTM D790: Flexural Properties of Reinforced Plastics

-

EN 13706: Structural Profiles Made of Pultruded FRP

-

UL 94: Fire Resistance Rating

Installation and Handling

-

Can be easily cut, drilled, and assembled using standard woodworking tools.

-

Should be handled with care to avoid damage to the surface coating.

-

Use suitable fastening systems such as stainless steel or composite fasteners for long-term durability.

-

Proper storage is recommended to prevent warping or exposure to extreme weather before installation.

Cost Efficiency

While the initial cost of FRP square tubes may be higher than traditional materials, they offer long-term savings due to:

-

Reduced maintenance costs

-

Longer lifespan

-

Minimal replacement requirements

-

Lower transportation and handling costs due to their lightweight nature

Conclusão

FRP square tubes provide a superior alternative to conventional materials in various industries. Their strength, durability, corrosion resistance, and lightweight nature make them ideal for demanding applications. With a wide range of specifications, compliance with international standards, and extensive application possibilities, FRP square tubes are the future of structural materials. Whether in construction, marine, electrical, or industrial settings, investing in FRP square tubes ensures reliability, longevity, and overall performance excellence.

Tubo Quadrado FRP

Series :

Principais Produtos >aplicativo

Marca :

TFcomposite

Nome do Produto :

Tubo Quadrado FRP

Material:

Fibra de vidro

Cor :

Yellow,Gray

Processamento Final:

Suave

Perguntas frequentes

P:

What is the typical lifespan of FRP square tubes?

A :

FRP square tubes can last over 50 years in most applications due to their high durability and resistance to environmental factors.

P:

Are FRP square tubes fire-resistant?

A :

Yes, FRP square tubes can be manufactured with fire-retardant resins to meet safety standards like UL 94.

P:

Can FRP square tubes replace steel in structural applications?

A :

Yes, in many cases, FRP square tubes can replace steel, offering comparable strength with significant weight reduction and corrosion resistance.

P:

How do I cut and install FRP square tubes?

A :

FRP square tubes can be cut with standard carbide-tipped saws and installed using stainless steel or composite fasteners.

P:

Are FRP square tubes resistant to UV exposure?

A :

Yes, they are manufactured with UV-resistant additives to prevent degradation from sunlight exposure.

P:

What colors are available for FRP square tubes?

A :

Standard colors include gray, yellow, and green, but custom colors are available upon request.

P:

Can FRP square tubes be painted?

A :

Yes, they can be painted using appropriate coatings designed for fiberglass materials.

P:

Are FRP square tubes recyclable?

A :

FRP materials are not easily recyclable due to their composite nature, but they offer long-term sustainability due to their extended lifespan and low maintenance needs.

Outros produtos relacionados