O Galvanized Steel Grating Step Board is a rugged, durable, and safety-enhanced platform solution widely used in industrial, commercial, and infrastructural environments. Designed specifically for applications such as stair treads, access walkways, elevated platforms, mezzanines, and safety ladders, this product offers high load-bearing capacity, excellent anti-slip features, corrosion resistance, and minimal maintenance requirements.

Introdução ao desempenho do produto

With superior manufacturing standards and hot-dip galvanizing treatment, the galvanized steel step board offers outstanding performance even in harsh environments such as chemical plants, offshore platforms, shipyards, power plants, and mining operations. It is engineered to ensure maximum safety, strength, and long-term reliability.

2. Product Overview

Product Name:

Galvanized Steel Grating Step Board

Material Composition:

Low-carbon steel (Q235 or equivalent), stainless steel available upon request.

Surface Treatment:

Hot-dip galvanized per ASTM A123 / ISO 1461

Production Technique:

-

Welded grating: Electro-forged pressure resistance welding

-

Press-locked grating: Press-locked with high mechanical precision

-

Custom options: Serrated, plain, or I-bar profile

3. Key Features and Benefits

✅ 1. High Strength and Load-Bearing Capacity

Galvanized steel step boards can withstand heavy dynamic and static loads due to their structural integrity, making them ideal for industrial stairs and platforms.

✅ 2. Superior Anti-Corrosion

The hot-dip galvanizing process creates a zinc coating that provides long-term corrosion resistance, even in extreme weather or corrosive environments such as offshore or chemical areas.

✅ 3. Enhanced Safety

Optional serrated surface or anti-skid nosing offers maximum slip resistance, reducing the risk of accidents in wet, oily, or icy conditions.

✅ 4. Low Maintenance

Galvanized finish minimizes rusting and deterioration, reducing the need for frequent maintenance and repair, thus lowering the total cost of ownership.

✅ 5. Easy Installation

Available with pre-drilled holes or bolted attachment systems, the step boards are easy to install or replace, and they can be cut to custom sizes for unique structural requirements.

✅ 6. Wide Range of Applications

Used across sectors including oil & gas, chemical processing, mining, water treatment plants, marine operations, and public transportation infrastructures.

4. Product Specifications

| Parâmetro | Value / Range |

|---|---|

| Material | Q235 Carbon Steel, Stainless Steel 304/316 |

| Acabamento de superfície | Hot-Dip Galvanized (70–100 μm zinc layer) |

| Standard Size (L × W) | 600 mm × 240 mm, 700 × 270 mm, or custom |

| Bearing Bar Pitch | 30 mm, 40 mm, or 60 mm |

| Cross Bar Pitch | 50 mm or customized |

| Thickness of Bearing Bar | 3 mm to 6 mm |

| Grating Type | Plain, Serrated, I-bar |

| Weight Load Capacity | Up to 10 kN/m² or as per requirement |

| Surface Pattern | Plain or Serrated |

| Anti-slip Options | Checkered plate nosing, serrated bar |

| Standards | ANSI/NAAMM MBG531, BS 4592, ISO 9001 |

| Galvanizing Standard | ASTM A123 / ISO 1461 |

| Resistência ao fogo | Excellent (Non-combustible) |

| Recyclability | 100% recyclable |

5. Technical Data Sheet (TDS)

5.1 Material Properties

| Propriedade | Valor |

|---|---|

| Yield Strength (Q235) | ≥ 235 MPa |

| Resistência à tracção | ≥ 370 MPa |

| Alongamento | ≥ 20% |

| Modulus of Elasticity | 200 GPa |

| Densidade | 7.85 g/cm³ |

| Melting Point | ~1425–1540 °C |

5.2 Zinc Coating Thickness (Galvanized Surface)

| Coating Type | Zinc Thickness | Corrosion Resistance Life (avg) |

|---|---|---|

| Hot-dip Galvanized | 70–100 µm | 25–40 years (industrial exposure) |

6. Types of Steel Grating Step Boards

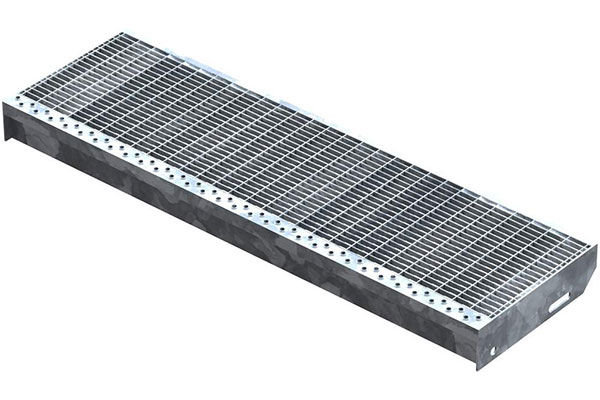

6.1 Welded Steel Grating Step Board

-

Bearing bars and cross bars are pressure welded

-

Available in plain or serrated surface

-

Most common for stair treads in heavy-duty use

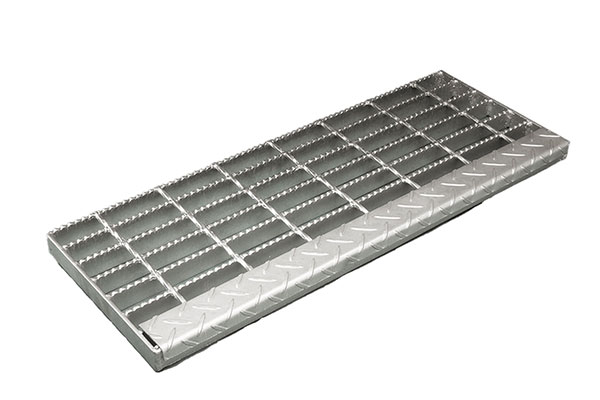

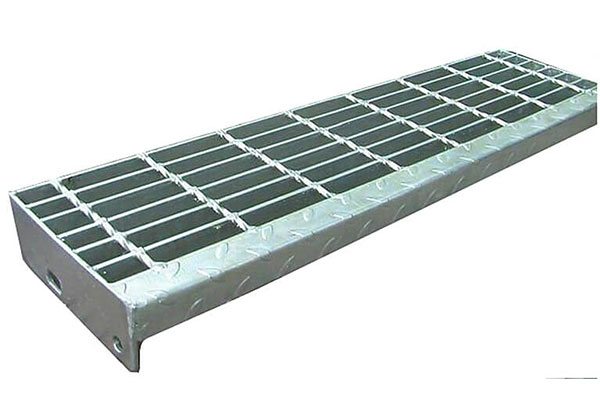

6.2 Press-Locked Grating Step Board

-

High precision pressing

-

Aesthetically clean

-

Often used in architectural or commercial staircases

6.3 Swage-Locked Step Board

-

High-strength swaging process used to bond cross bars

-

Lighter weight, suitable for moderate load applications

7. Anti-Slip Nosing Options

| Nosing Type | Descrição |

|---|---|

| Checkered Plate | Embossed steel plate added to front edge for visual & anti-slip protection |

| Yellow Painted Edge | Visual safety marking for high foot traffic zones |

| Serrated Nosing | Additional grip on stairs for heavy-duty applications |

8. Applications

✅ Instalações Industriais

Used as stair treads for access stairs, maintenance platforms, and mezzanine floors in factories and plants.

✅ Energy & Petrochemical Plants

Resistant to corrosion from chemicals and moisture, suitable for oil rigs, refineries, and offshore platforms.

✅ Infraestrutura Pública

Ideal for metro stations, pedestrian bridges, and access platforms in transport terminals.

✅ Water Treatment & Dams

Non-slip and corrosion-resistant performance make it ideal for wet or underwater applications.

✅ Mining & Quarrying

Supports heavy-duty foot traffic and equipment access in rugged and dusty environments.

✅ Architectural & Commercial

Modern staircases, decorative balconies, and industrial-style interiors benefit from the strength and design flexibility.

9. Standards and Certifications

-

ISO 9001:2015 Quality Management System

-

ASTM A36 / A1011 – Structural Steel Standards

-

EN ISO 1461 / ASTM A123 – Hot-Dip Galvanizing

-

NAAMM MBG531-09 – Metal Bar Grating Manual

-

CE Marking – For compliance in European markets

10. Customization Options

-

Dimensões: Length, width, and height can be cut to customer needs

-

Surface: Plain, serrated, or anti-slip coating

-

Fixing Method: Bolted, welded, or clip-on

-

Material Choice: Stainless steel or powder-coated versions

-

Painted Edge: Safety color-coded nosing (yellow, red)

11. Quality Assurance & Testing

Each galvanized steel grating step board undergoes a strict quality control process to ensure compliance with industrial standards. Testing includes:

-

Load-bearing capacity test

-

Galvanizing adhesion and thickness measurement

-

Anti-slip coefficient test (ASTM D2047)

-

Visual inspection for welding integrity

-

Dimensional accuracy checks

12. Packaging & Delivery

Embalagem

-

Steel pallet with PE wrapping or wooden box

-

Each piece labeled for tracking and installation

Entrega

-

Lead time: 10–15 working days for standard sizes

-

Custom orders: 20–25 working days

13. Installation Guidelines

-

Measurement: Measure the stair dimensions for accurate sizing.

-

Support Frame: Ensure steel frames or channels are pre-installed.

-

Fixing: Use bolts, welding, or saddle clips to install.

-

Alignment: Align step boards for consistent rise and run.

-

Inspeção: Check for level installation and anti-slip alignment.

14. Maintenance Instructions

-

Routine Inspection: Every 6–12 months, especially for bolts or welds

-

Limpeza: Use mild soap and water, avoid acidic cleaners

-

Rust Check: Though unlikely, touch up if zinc layer is damaged

-

Replacement: If bent or corroded, replace the unit to maintain safety

15. Environmental Impact

Steel grating is a 100% recyclable product. The galvanizing process, though energy-intensive, provides decades of protection, thereby reducing the need for replacements and conserving material resources over time. Most factories comply with ROHS and REACH standards for sustainable manufacturing.

16. Frequently Asked Questions (FAQ)

Q: How long does galvanized grating last?

A: Typically 25–40 years in industrial environments and longer in dry, indoor use.

Q: Can step boards be used outdoors?

A: Yes. They are ideal for outdoor use due to their corrosion resistance and durability.

Q: What is the difference between plain and serrated?

A: Serrated has a jagged edge for better grip, especially in slippery areas.

Q: Can I get non-standard sizes?

A: Absolutely. Custom fabrication is available upon request.

17. Conclusion

O Galvanized Steel Grating Step Board is a high-performance, long-lasting solution for safe and efficient stair access in industrial and commercial environments. Its robust design, slip-resistant features, and weatherproof finish make it a superior choice for demanding applications. Whether you require standard sizing or custom configurations, this product delivers reliable support, compliance with international safety standards, and a long service life.

Galvanized steel grating Step board

Series :

Produtos proxy >aplicativo

Industrial Facilities Used as stair treads for access stairs, maintenance platforms, and mezzanine floors in factories and plants. ✅ Energy & Petrochemical Plants Resistant to corrosion from chemicals and moisture, suitable for oil rigs, refineries, and offshore platforms. ✅ Public Infrastructure Ideal for metro stations, pedestrian bridges, and access platforms in transport terminals. ✅ Water Treatment & Dams Non-slip and corrosion-resistant performance make it ideal for wet or underwater applications. ✅ Mining & Quarrying Supports heavy-duty foot traffic and equipment access in rugged and dusty environments. ✅ Architectural & Commercial Modern staircases, decorative balconies, and industrial-style interiors benefit from the strength and design flexibility.

Marca :

TFcomposite

Nome do Produto :

Galvanized steel grating Step board

Perguntas frequentes

P:

What materials are used for steel grating step boards?

A :

Most step boards are made from low-carbon steel (Q235) and then hot-dip galvanized. Some variants use stainless steel for added corrosion resistance in highly corrosive environments.

P:

Why choose hot-dip galvanized grating?

A :

Hot-dip galvanizing forms a strong zinc layer on the steel surface, offering: Long-lasting corrosion resistance Maintenance-free protection Resistance to mechanical wear and chemical exposure

P:

What is the difference between plain and serrated step boards?

A :

Plain type: Smooth bearing bar, used in dry, clean environments. Serrated type: Jagged surface provides anti-slip functionality for wet, oily, or outdoor areas.

P:

How are the step boards installed?

A :

They can be: Bolted using pre-drilled side plates Welded onto stair supports Clipped with saddle clamps for removable steps

P:

What is “nosing” on a step board?

A :

Nosing is the front edge of the step board. It improves visibility and anti-slip performance. Types include: Checkered plate nosing Serrated nosing Painted safety edge (e.g., yellow)

Outros produtos relacionados