Glass Fiber Powder is a finely milled form of E-glass fibers, engineered to enhance the mechanical and thermal properties of various composite materials. Its unique characteristics make it a valuable additive in industries such as automotive, construction, aerospace, and electronics.

Introdução ao desempenho do produto

Glass Fiber Powder is a finely milled form of E-glass fibers, engineered to enhance the mechanical and thermal properties of various composite materials. Its unique characteristics make it a valuable additive in industries such as automotive, construction, aerospace, and electronics.

1. Product Overview

Chemical Identity:

-

Chemical Name: Glass Fiber Powder

-

Composição: Primarily E-glass (Alumino-borosilicate glass)

-

CAS Number: 65997-17-3

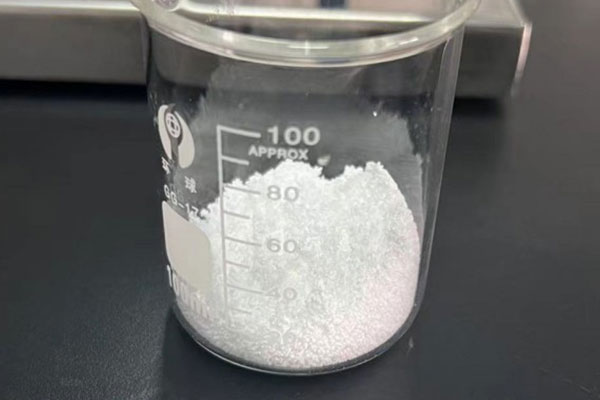

Physical Appearance:

-

White or off-white powder with varying fiber lengths and diameters, depending on the specific grade.

2. Technical Data Sheet (TDS)

2.1. General Properties:

| Propriedade | Typical Value |

|---|---|

| Appearance | White or off-white powder |

| Fiber Diameter | 9–14 μm |

| Specific Gravity | 2.60 g/cm³ |

| Softening Temperature | 840°C |

| Moisture Content | <0.3% |

| Tratamento da superfície | Silano |

| Loss on Ignition (LOI) | 0.3–1.5% |

| Resistência à tracção | 70–120 cN/tex |

| Modulus | 2800–3400 cN/tex |

2.2. Available Grades:

| Grade | Average Fiber Length (μm) | Bulk Density (kg/L) | Appearance | Flowability |

|---|---|---|---|---|

| EMG-50 | ≈50 | 0.65–0.75 | Powdery | Bom |

| EMG-100 | ≈100 | 0.50–0.65 | Powdery | Bom |

| EMG-200 | ≈200 | 0.30–0.40 | Slightly Flocculent | Average |

| EMG-400 | ≈300 | 0.25–0.28 | Flocculent | Pobre |

Note: Specific products can be customized according to customer requirements.

3. Key Properties

3.1. Mechanical Strength:

-

High tensile strength and modulus contribute to improved mechanical properties in composite materials.

3.2. Thermal Stability:

-

Softening temperature of 840°C allows for use in high-temperature applications.

3.3. Chemical Resistance:

-

Excellent resistance to most acids and alkalis, making it suitable for use in chemically aggressive environments.

3.4. Electrical Insulation:

-

High volume resistivity (10¹¹–10¹⁸ Ω·cm) provides excellent electrical insulation properties.

3.5. Dimensional Stability:

-

Low coefficient of thermal expansion (~5×10⁻⁶/°C) ensures dimensional stability under temperature fluctuations.

4. Applications

4.1. Automotive Industry:

-

Used in manufacturing lightweight, high-strength parts such as body panels, bumpers, and under-the-hood components.

-

Enhances the mechanical properties of automotive putties and coatings.

4.2. Construction Industry:

-

Reinforces concrete, mortar, and other building materials to improve crack resistance and structural integrity.

-

Used in wall putties and coatings for enhanced durability and moisture resistance.

4.3. Aerospace Industry:

-

Incorporated into composite materials for aircraft components to reduce weight while maintaining strength.

4.4. Electronics Industry:

-

Enhances the mechanical and thermal properties of printed circuit boards (PCBs) and other electronic components.

4.5. Coatings and Paints:

-

Improves the mechanical properties and durability of various coatings and paints.

5. Safety and Handling

-

Personal Protective Equipment (PPE): Use appropriate PPE, including gloves, safety goggles, and dust masks, to prevent skin and eye contact and inhalation of dust.

-

Armazenar: Store in a cool, dry, and well-ventilated area. Keep containers tightly closed to prevent moisture absorption.

-

Handling: Avoid generating dust. Use local exhaust ventilation to minimize airborne concentrations.

6. Packaging and Storage

-

Embalagem: Typically available in 20 kg or 25 kg bags, with inner polyethylene liners and outer fiber drums or cartons.

-

Condições de armazenamento: Store at temperatures between 15°C and 35°C, with relative humidity between 35% and 85%.

-

Shelf Life: Under recommended storage conditions, the product maintains its properties for up to 12 months.

7. Conclusion

Glass Fiber Powder is a versatile and high-performance material that enhances the mechanical, thermal, and chemical properties of various composites. Its wide range of applications across multiple industries underscores its importance as a reinforcing agent. Proper handling and storage ensure the material's longevity and performance in end-use applications.

Glass Fiber Powder

Series :

Fiberglass Accessories >aplicativo

Automotive Industry,Construction Industry,Aerospace Industry,Electronics Industry,Coatings and Paints

Marca :

TFcomposite

Nome do Produto :

Glass Fiber Powder

Perguntas frequentes

P:

What is glass fiber powder?

A :

Glass fiber powder is a finely ground product made by crushing or milling E-glass fibers or C-glass fibers into a powder form. It retains the physical and chemical properties of glass fibers and is widely used as a reinforcing filler in various resin and polymer systems.

P:

What is the typical particle size of glass fiber powder?

A :

Glass fiber powder typically has a D50 (median particle size) ranging from 10 μm to 100 μm, depending on the manufacturing process and application requirements. Custom specifications can be produced for niche applications.

P:

Is glass fiber powder hydrophobic or hydrophilic?

A :

Raw glass fiber powder is typically hydrophilic, but surface-treated (e.g., with silane coupling agents) variants are available to improve compatibility with hydrophobic resins like polypropylene (PP) and polyethylene (PE).

P:

Is glass fiber powder compatible with all resins?

A :

While it is inherently compatible with many thermoset resins (like polyester and epoxy), for thermoplastics, the surface may need to be treated (e.g., silanized) to enhance resin wet-out and bonding.

Outros produtos relacionados