o-Phthalic Unsaturated Polyester Resin is a thermosetting polymer formed by the condensation reaction of o-phthalic anhydride, glycols (such as propylene glycol or ethylene glycol), e unsaturated acids like maleic anhydride. The result is a highly reactive resin system, commonly dissolved in styrene monomer, which acts as both a reactive diluent and a crosslinking agent during curing.

Introdução ao desempenho do produto

This type of resin is part of the broader unsaturated polyester resin (UPR) family, but its unique formulation centered around ortho-phthalic acid gives it distinct performance traits and economic advantages.

🧬 2. Chemical Structure and Characteristics

-

Base Monomer: o-Phthalic anhydride

-

Reactive Diluents: Styrene (typically 30–40%)

-

Curing System: Free radical initiated (typically MEKP or BPO)

-

Polymer Backbone: Linear with unsaturated sites enabling crosslinking

🧱 3. Key Properties

| Category | Detalhes |

|---|---|

| Curing Mechanism | Thermosetting via free-radical crosslinking |

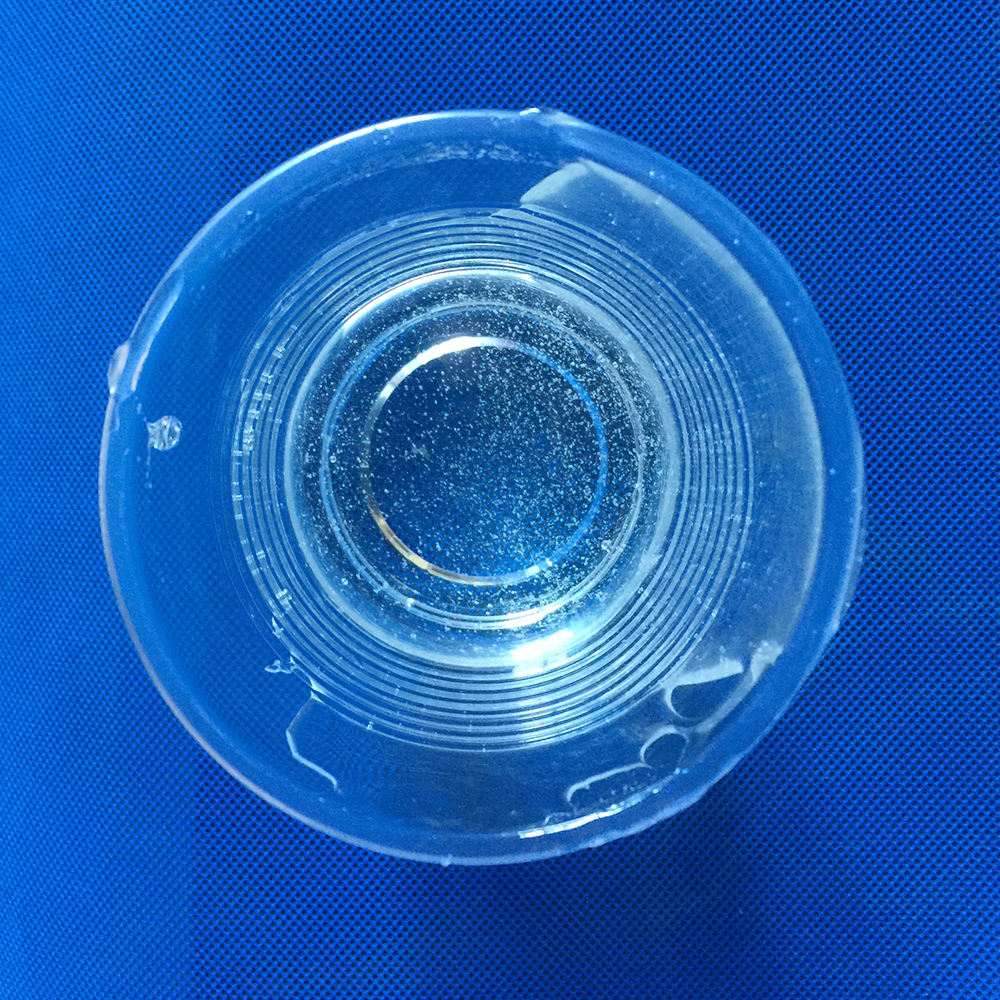

| Physical Appearance | Clear to light yellow viscous liquid |

| Viscosidade | 400–1200 cps at 25°C (depends on formulation) |

| Tempo de gel | Adjustable between 5–20 minutes (at 25°C with 1% MEKP) |

| Reactivity | Medium to high depending on initiator level and accelerator system |

| Resistência térmica | Up to 90–100°C continuous, higher with heat post-cure |

| Mechanical Strength | Excellent tensile and flexural properties |

| Resistência química | Good against dilute acids, water, and oils |

| Electrical Properties | Good dielectric strength and surface resistivity |

🏭 4. Manufacturing and Processing

o-Phthalic resin is manufactured in closed reactors by:

-

Reacting phthalic anhydride and glycols under controlled heating (~200°C)

-

Adding maleic anhydride to introduce unsaturation

-

Diluting the resin with styrene monomer to adjust viscosity

-

Stabilizing the resin with inhibitors (e.g., hydroquinone) for shelf life

The final product is shipped as a viscous liquid, ready for curing using peroxides.

🛠️ 5. Applications

🧰 General-Purpose Composites

-

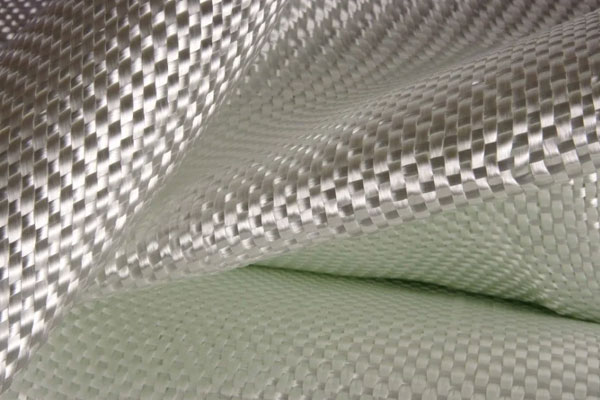

Fiberglass Reinforced Plastics (FRP): panels, bathtubs, septic tanks

-

FRP Gratings & Covers: industrial floors, stair treads, trench covers

-

Boat hulls and watercraft structures

-

Cooling tower components

-

Storage tanks (non-chemical-grade)

🏗️ Construction & Building

-

Molded decorative components

-

Skylight domes

-

Concrete form liners

-

Partition boards

-

Roofing sheets

🚛 Automotive & Transportation

-

Truck bodies and paneling

-

Trailer coverings

-

Air deflectors

🧾 6. Technical Data Sheet (TDS)

| Propriedade | Value (Typical) | Test Method / Notes |

|---|---|---|

| Appearance | Light yellow / Clear | Visual |

| Viscosity @ 25°C (Brookfield) | 450–850 cps | ASTM D2196 |

| Acid Value (mg KOH/g) | 20–30 | ASTM D4662 |

| Gel Time (25°C, 1% MEKP) | 8–15 minutes | ASTM D2471 |

| Peak Exotherm Temp | 140–160°C | Internal Test |

| Volatile Content (Styrene) | 30–40% | ASTM D2369 |

| Specific Gravity @ 25°C | 1.10–1.15 | ASTM D1475 |

| Flash Point (Closed Cup) | 32–33°C | ASTM D3278 |

| Shelf Life | 3–6 months (inhibitor added) | At 25°C, in sealed containers |

After Cure (Fully Laminated with Glass Fiber)

| Mechanical Property | Typical Value | Método de teste |

|---|---|---|

| Resistência à tracção | 60–80 MPa | ASTM D638 |

| Tensile Modulus | 3.5–4.5 GPa | ASTM D638 |

| Resistência à flexão | 110–130 MPa | ASTM D790 |

| Módulo de Flexão | 4.5–6.0 GPa | ASTM D790 |

| Impact Strength (Izod) | 8–12 kJ/m² | ASTM D256 |

| Heat Deflection Temp (HDT) | 60–90°C | ASTM D648 |

| Dureza Barcol | 35–45 | ASTM D2583 |

| Water Absorption (24h @ 23°C) | < 0.5% | ASTM D570 |

🧬 7. Key Advantages

-

✔️ Cost-effective – most economical among UPR types

-

✔️ Moderate chemical resistance – good for water, oil, and weathering

-

✔️ Fast curing – adaptable to a wide range of catalysts and accelerators

-

✔️ Good mechanical strength – ideal for structural applications

-

✔️ Compatibility – works well with fillers, pigments, and reinforcements

⚠️ 8. Limitations

-

❌ Not suitable for aggressive chemical environments (acids/alkalis)

-

❌ Lower HDT than isophthalic or bisphenol-based resins

-

❌ Styrene emissions during processing may require ventilation

-

❌ Limited UV resistance unless topcoated or pigmented

-

❌ Shorter shelf life compared to pre-accelerated resins

📦 9. Packaging & Storage

-

Standard Packaging:

-

220 kg metal drums

-

1000 kg IBC totes

-

Bulk tankers available upon request

-

-

Storage Conditions:

-

Store between 5–25°C

-

Avoid direct sunlight and ignition sources

-

Keep containers sealed when not in use

-

Add inhibitors for long-term storage

-

🧯 10. Health, Safety & Handling

-

Wear appropriate PPE: gloves, goggles, respirators

-

Ventilate areas during mixing and curing

-

Avoid contact with skin or eyes; in case of exposure, rinse immediately

-

Styrene vapors are flammable – use in explosion-proof areas

-

Dispose of curing residues according to local environmental regulations

Refer to the MSDS (Material Safety Data Sheet) for more detailed guidelines.

🧪 11. Comparison with Other UPR Types

| Propriedade | o-Phthalic Resin | Isophthalic Resin | Bisphenol Resin | Éster vinílico |

|---|---|---|---|---|

| Custo | Baixo | Medium | Alto | Muito alto |

| Resistência química | Moderado | Alto | Muito alto | Excelente |

| Mechanical Strength | Bom | Very Good | Excelente | Excelente |

| Resistência térmica | Moderado | Alto | Muito alto | Alto |

| Curing Speed | Rápido | Moderado | Slow (long pot life) | Moderado |

| Formulários | General-purpose | Structural, marine | Corrosive tanks | Pipes, CIPP, tanks |

❓ 12. Frequently Asked Questions (FAQ)

Q1: Can I use o-phthalic resin in contact with drinking water?

Not recommended unless certified and post-cured under specific hygiene standards.

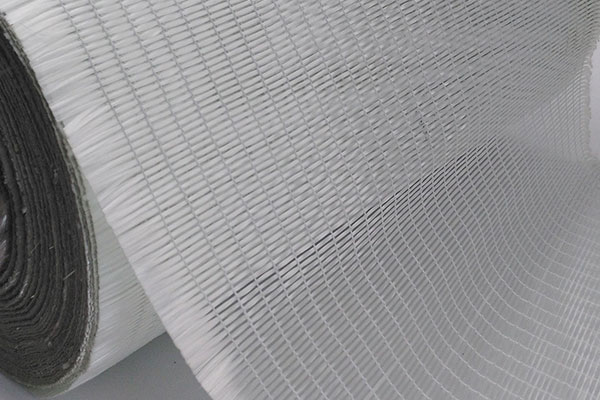

Q2: What is the ideal reinforcement to use?

Chopped strand mat, woven roving, or stitched fabrics depending on application. For strength-critical parts, use 600gsm or higher.

Q3: Can it be pigmented?

Yes, use color pastes compatible with polyester resins. Add pigment before adding initiator.

Q4: What accelerators are compatible?

Cobalt octoate (Co-octoate) is common. Others include DMA and potassium peroxodisulfate (KPS).

Q5: Can I adjust the gel time?

Yes. Modify initiator/accelerator levels or temperature. Always validate gel and peak exotherm for safety.

🏁 13. Conclusion

o-Phthalic Unsaturated Polyester Resin is a cost-effective, versatile solution for numerous composite applications. While it offers excellent mechanical strength and processing ease, it’s best suited for non-aggressive environments or general-purpose parts. For industrial-scale FRP production where economics meet acceptable performance, it remains a popular, reliable option.

When processed with care and combined with the right reinforcements, this resin delivers consistent and high-quality results across construction, transport, marine, and industrial applications.

o-Phthalic Unsaturated Polyester Resin

Series :

Produtos proxy >aplicativo

revestimentos, adesivos e compósitos

Nome do Produto :

o-phthalic resin

Perguntas frequentes

P:

What are the main applications of o-Phthalic Unsaturated Polyester Resin?

A :

o-Phthalic UPR is widely used in general-purpose fiberglass-reinforced plastic (FRP) applications such as gratings, tanks, bathtubs, pipes, panels, and decorative components. It is especially suited for environments requiring moderate mechanical strength and cost-efficiency, but not intended for aggressive chemical or high-temperature conditions.

P:

How does it compare to isophthalic and vinyl ester resins?

A :

Cost: o-Phthalic is more economical. Performance: It has lower chemical and thermal resistance compared to isophthalic or vinyl ester resins. Usage: Choose o-Phthalic for general use, isophthalic for stronger corrosion/thermal needs, and vinyl ester for high-performance or corrosive environments.

P:

How do I store and handle o-Phthalic resin safely?

A :

Store in cool (5–25°C), dry, well-ventilated areas. Keep away from heat, ignition sources, and sunlight. Use sealed containers, ideally nitrogen-blanketed. Always wear protective gloves, goggles, and use fume extraction when handling. Follow your supplier's MSDS for detailed safety procedures.

P:

Can o-Phthalic resin be pigmented or filled?

A :

Yes. o-Phthalic resin is compatible with polyester-compatible pigments and fillers (e.g., calcium carbonate, ATH). Add pigments and fillers before mixing in the curing agents. Keep the viscosity in check if adding fillers to avoid poor wet-out of reinforcements.

P:

How long is the shelf life of o-Phthalic resin, and how can it be extended?

A :

Typical shelf life is 3 to 6 months when stored in ideal conditions (below 25°C in a sealed container). To extend shelf life: Ensure resin is stabilized with hydroquinone or MEHQ inhibitors. Store in dark, cool environments. Avoid frequent opening of containers to limit oxygen and moisture exposure.

Outros produtos relacionados