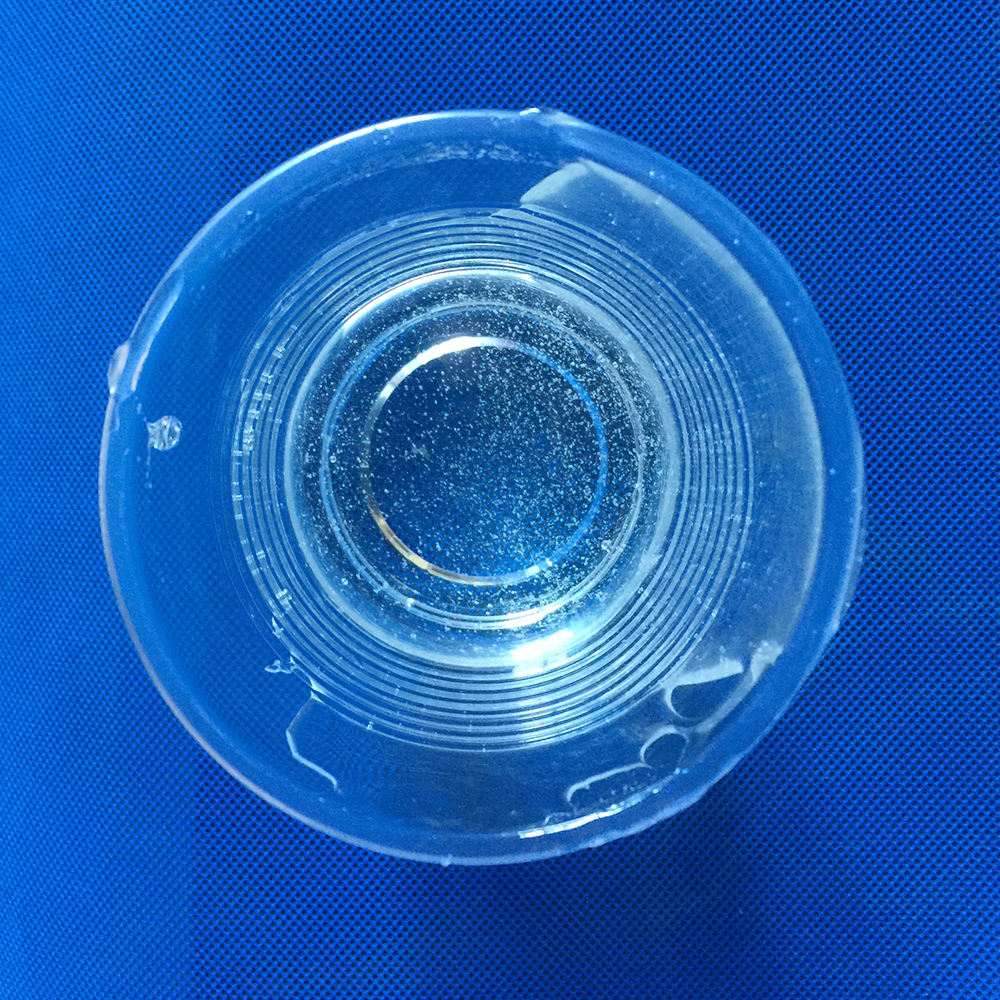

Paraphthalic Unsaturated Polyester Resin, often abbreviated as P-UPR, is a high-performance resin engineered for superior chemical resistance, thermal stability, e mechanical strength. It is synthesized using terephthalic acid (commonly referred to as para-phthalic acid due to its molecular structure) as a key raw material. As a member of the aromatic polyester resin family, paraphthalic resin surpasses the performance of both orthophthalic e isophthalic variants in several critical areas.

Introdução ao desempenho do produto

This document will explore the properties, advantages, applications, processing methods, and provide a comprehensive Technical Data Sheet (TDS). Designed to meet the demands of industries such as chemical processing, marine, automotivo, e infrastructure, paraphthalic resin is the material of choice when longevity and resistance to extreme environments are essential.

2. What is Paraphthalic Unsaturated Polyester Resin?

Paraphthalic UPR is a thermosetting resin derived from terephthalic acid ou dimethyl terephthalate (DMT), which is reacted with glycols such as propylene glycol ou neopentyl glycol e maleic anhydride. It contains unsaturated double bonds that allow cross-linking with monomers like styrene during curing, forming a three-dimensional network with high structural integrity.

What makes paraphthalic resin unique is its benzene ring structure in the para position, which confers rigidity and thermal resistance. This molecular arrangement makes P-UPR one of the most durable and stable resins available within the unsaturated polyester family.

3. Key Features and Benefits

✅ Outstanding Chemical Resistance

Tolerates prolonged exposure to acids, alkalis, salts, and a variety of organic solvents.

✅ Exceptional Mechanical Properties

High tensile, flexural, and impact strength ideal for structural and load-bearing applications.

✅ Superior Thermal Stability

Heat resistance up to 160°C with special formulations.

✅ Enhanced Weathering Resistance

Performs well under UV radiation, freeze-thaw cycles, and high humidity environments.

✅ Long Service Life

Designed for applications demanding 20+ years of durability.

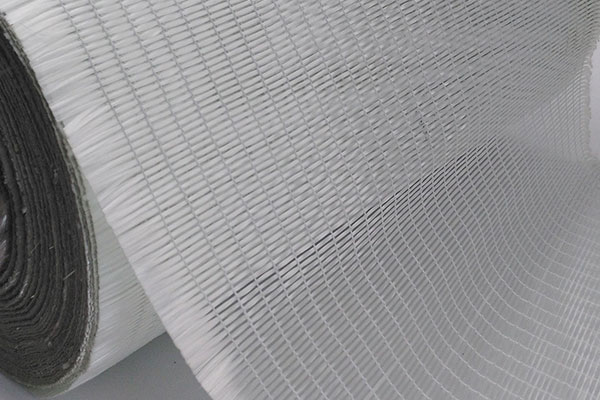

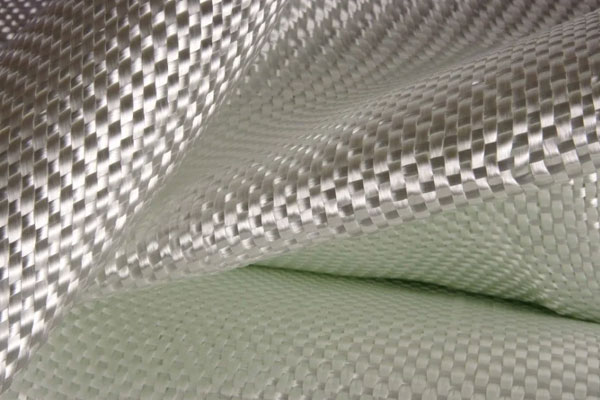

✅ Excellent Compatibility with Reinforcements

Bonds exceptionally well with glass, aramid, and carbon fiber for high-strength composites.

4. Common Applications

Paraphthalic UPR is used across a wide range of industries that demand high-performance, corrosion-resistant composite materials.

| Industry | Formulários |

|---|---|

| Processamento Químico | FRP tanks, scrubbers, pipes, ducting, and containment systems |

| Marinho | Hulls, decks, fishing boats, docks, and marine gratings |

| Construção | Grating panels, cable trays, bridge decks, structural reinforcements |

| Tratamento de Água | Wastewater tanks, flow channels, and covers |

| Transporte | Automotive bumpers, trailer panels, composite parts |

| Electrical | Insulation panels, junction boxes, and cable carriers |

| A infraestrutura | Road barriers, rail platforms, water management components |

5. Processing Characteristics

Paraphthalic UPR is suitable for various fabrication processes. It is often supplied as a pre-promoted system but may also be modified to suit specific production techniques.

| Processing Method | Suitability |

|---|---|

| Hand Lay-up | Excelente |

| Spray-up | Excelente |

| Pultrusion | Very Good (requires low viscosity) |

| Filament Winding | Very Good |

| Vacuum Infusion | Good with adjusted viscosity |

| Compression Molding | Acceptable |

Curing Agents:

Paraphthalic resins cure with MEKP, BPO, ou AIBN, often in conjunction with cobalt accelerators.

Tempo de gel:

Adjustable between 8–25 minutes depending on application and catalyst system.

6. Technical Data Sheet (TDS)

Below is a representative TDS. The actual properties may vary depending on the manufacturer or the specific formulation.

📌 Liquid Resin Properties

| Propriedade | Typical Value | Método de teste |

|---|---|---|

| Appearance | Pale yellow to amber liquid | Visual |

| Viscosity @ 25°C (mPa·s) | 450 – 700 | Brookfield, #3/60rpm |

| Acid Number (mg KOH/g) | 12 – 22 | ISO 2114 |

| Solid Content (%) | 62 – 68 | ISO 3251 |

| Styrene Content (%) | 30 – 38 | Gas Chromatography |

| Gel Time @ 25°C (1% MEKP) | 10 – 18 minutes | ISO 2535 |

| Peak Exotherm Temperature (°C) | 140 – 180 | In-house method |

| Flash Point | ~32°C | ASTM D93 |

| Shelf Life | 6 months @ ≤ 25°C | - |

🔧 Cured Resin Mechanical Properties

| Propriedade | Typical Value | Método de teste |

|---|---|---|

| Tensile Strength (MPa) | 75 – 100 | ISO 527 |

| Tensile Modulus (GPa) | 3.2 – 3.6 | ISO 527 |

| Elongation at Break (%) | 2.5 – 4.0 | ISO 527 |

| Flexural Strength (MPa) | 120 – 140 | ISO 178 |

| Flexural Modulus (GPa) | 3.8 – 4.5 | ISO 178 |

| Izod Impact Strength (kJ/m²) | 9 – 12 | ISO 180 |

| Dureza Barcol | 40 – 50 | ASTM D2583 |

🌡️ Thermal and Chemical Resistance

| Propriedade | Typical Value | Método de teste |

|---|---|---|

| Heat Distortion Temperature (°C) | 110 – 130 | ISO 75 |

| Glass Transition Temperature (Tg) | 120 – 135 | DMA |

| Thermal Conductivity (W/m·K) | ~0.2 | ASTM C177 |

| Resistência química | Excellent in acid/alkali | ASTM C581 |

| Water Absorption (24h) (%) | < 0.25 | ISO 62 |

7. Storage Guidelines

To maintain the shelf life and quality of paraphthalic resin:

-

Store in sealed containers between 15–25°C.

-

Avoid direct sunlight, moisture, e excess heat.

-

Use within 6 months of manufacture date.

-

Agitate before use to ensure uniformity.

8. Safety Precautions

-

Follow MSDS recommendations.

-

Keep away from open flames e heat sources.

-

Avoid inhalation of styrene fumes; use in ventilated areas.

-

Wear appropriate PPE—gloves, goggles, and a respirator if needed.

-

Dispose of unused material in accordance with local regulations.

9. Packaging Options

Paraphthalic UPR is supplied in:

| Container Type | Net Weight |

|---|---|

| Steel Drum | 220–240 kg |

| IBC Tote | 1000 kg |

| ISO Tank | 20–24 MT |

10. Summary and Conclusion

Paraphthalic Unsaturated Polyester Resin stands out as a top-tier resin system for advanced composite applications. Its performance benefits over traditional ortho- and isophthalic resins include:

-

Enhanced resistance to corrosive environments.

-

Long-term thermal and UV stability.

-

Structural reliability in demanding mechanical applications.

Paraphthalic Unsaturated Polyester Resin (P-UPR)

Series :

Produtos proxy >aplicativo

revestimentos, adesivos e compósitos

Nome do Produto :

o-phthalic resin

Perguntas frequentes

P:

What is the main difference between paraphthalic resin and isophthalic or orthophthalic resins?

A :

The key difference lies in the acid component used during synthesis. Paraphthalic resin uses terephthalic acid, which has a para-configuration benzene ring structure. Isophthalic resin uses isophthalic acid (meta-configuration). Orthophthalic resin uses phthalic anhydride (ortho-configuration). This molecular difference gives P-UPR superior chemical resistance, thermal stability, and mechanical strength, making it more suitable for demanding industrial applications compared to isophthalic and orthophthalic resins.

P:

What industries benefit most from using paraphthalic unsaturated polyester resin?

A :

P-UPR is particularly beneficial in: Chemical processing plants (tanks, ducts, scrubbers) Marine industry (boat hulls, docks, gratings) Infrastructure and construction (bridges, water treatment) Electrical and electronics (cable trays, enclosures) Its high durability and corrosion resistance make it ideal for harsh and corrosive environments.

P:

Can P-UPR be used with fiberglass reinforcements like chopped strand mat or woven roving?

A :

Yes, absolutely. P-UPR is highly compatible with all standard reinforcements, including: Chopped strand mat (CSM) Woven roving Multiaxial fabrics Carbon fiber and aramid This compatibility results in excellent bonding, improving the structural strength and integrity of the final composite.

Outros produtos relacionados