Introdução ao desempenho do produto

Safety grating is a metal grating product specifically designed to enhance safety in industrial, commercial, and architectural applications. It is known for its slip resistance, strength, durability, and ability to provide ventilation and drainage. Safety grating is widely used in environments where worker safety and secure footing are critical, particularly in wet, oily, or hazardous conditions.

Key Features of Safety Grating

-

Anti-derrapante:

- The primary feature of safety grating is its high slip resistance, achieved through its unique surface patterns (e.g., serrated edges, perforations, or raised features).

-

Leve e durável:

- Made from strong yet lightweight materials, safety grating is easy to handle, install, and maintain.

-

Open Design:

- Allows for drainage of liquids, reducing the risk of pooling and providing ventilation.

-

Resistência à corrosão:

- Available with galvanized, painted, or stainless steel finishes to withstand corrosive environments.

-

Aplicações versáteis:

- Suitable for flooring, stair treads, platforms, walkways, and ladders in various industries.

-

Custo-beneficio:

- Combines durability with low maintenance, ensuring a long service life.

Specifications of Safety Grating

1. Materials

- Carbon Steel:

- Cost-effective and durable.

- Typically galvanized for corrosion resistance.

- Stainless Steel:

- Excellent corrosion resistance, ideal for harsh environments.

- Aluminum:

- Lightweight, corrosion-resistant, and suitable for environments where weight is a concern.

2. Surface Types

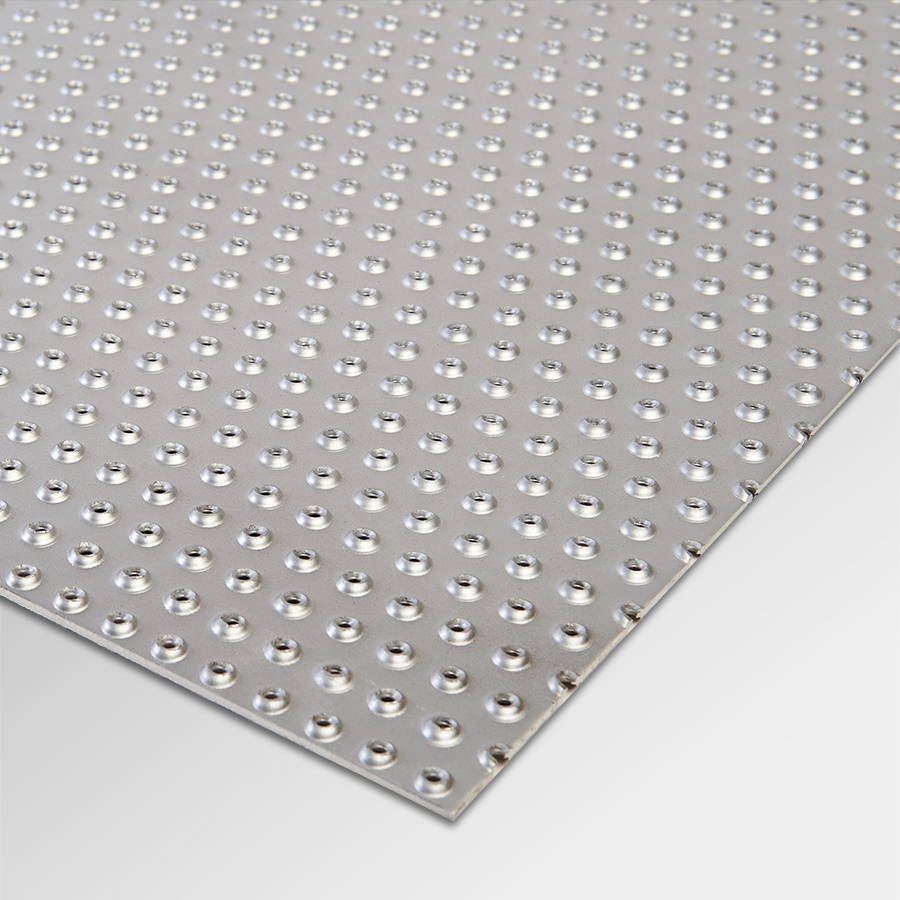

- Diamond Pattern:

- Raised diamonds provide superior slip resistance and drainage.

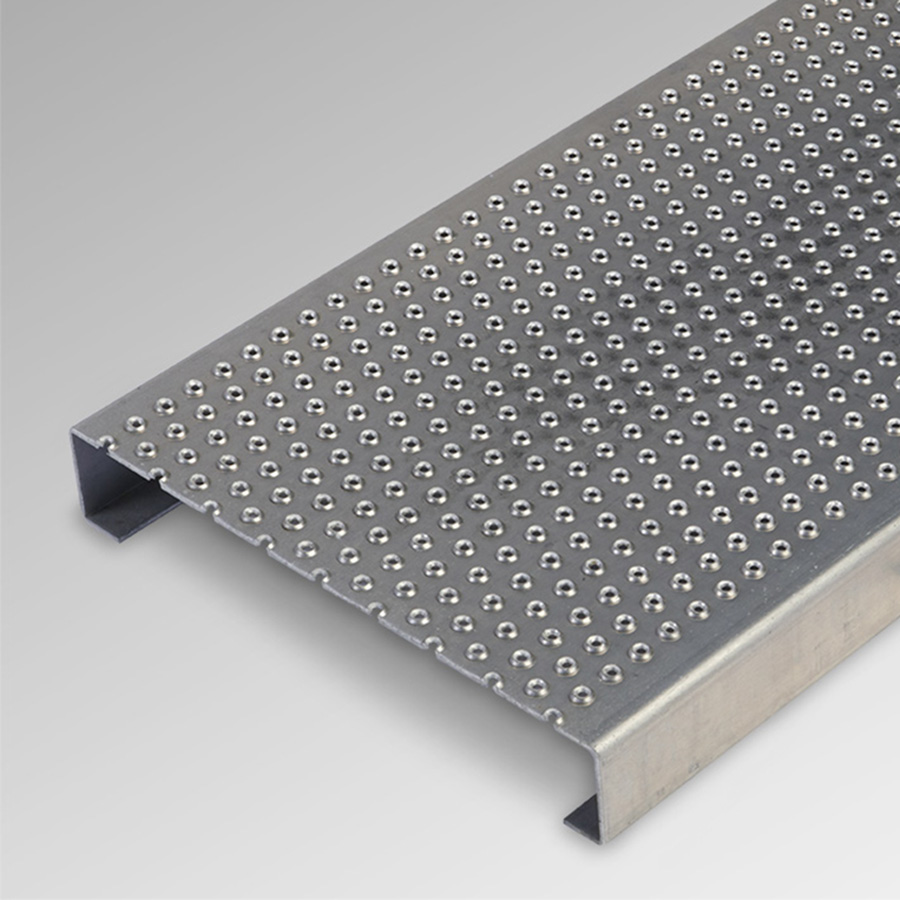

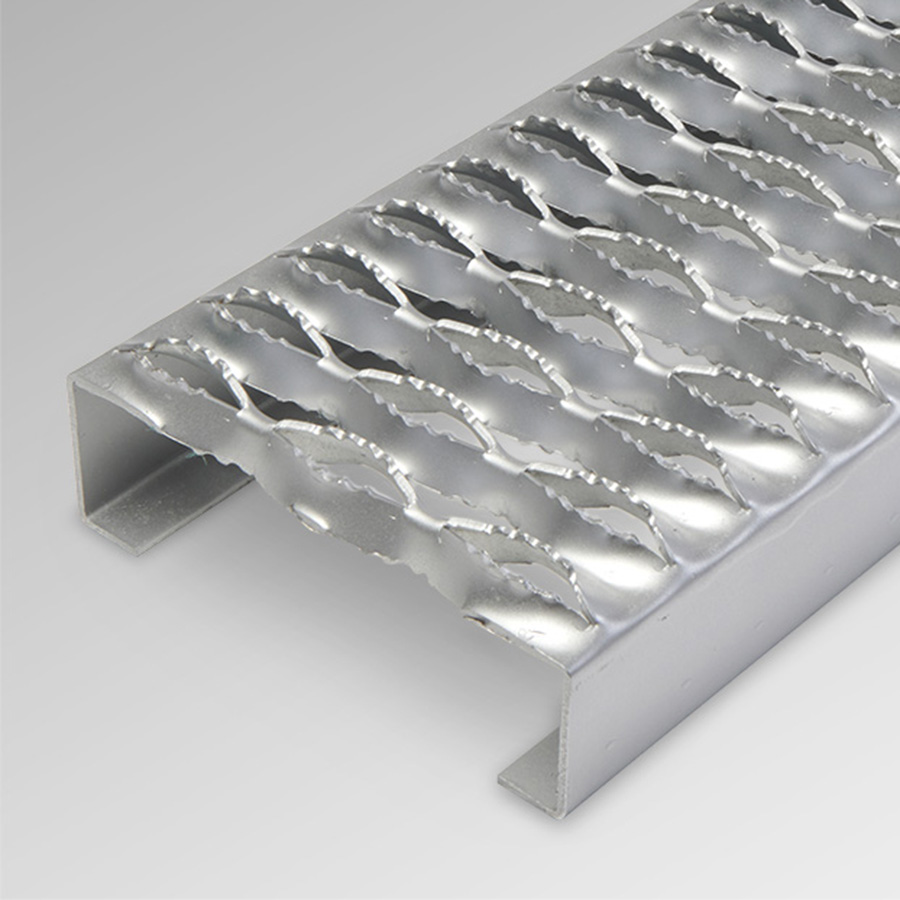

- Plank Grating:

- Features perforated or serrated surfaces for added traction.

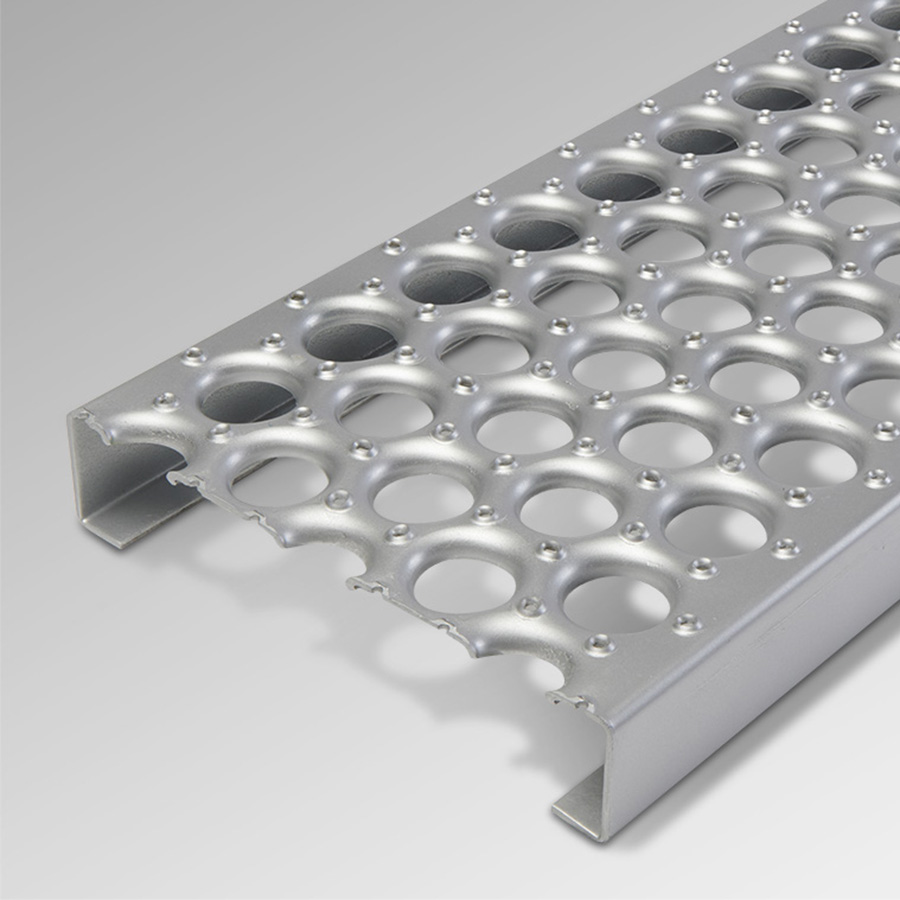

- Round Hole Grating:

- Circular perforations enhance drainage and ventilation.

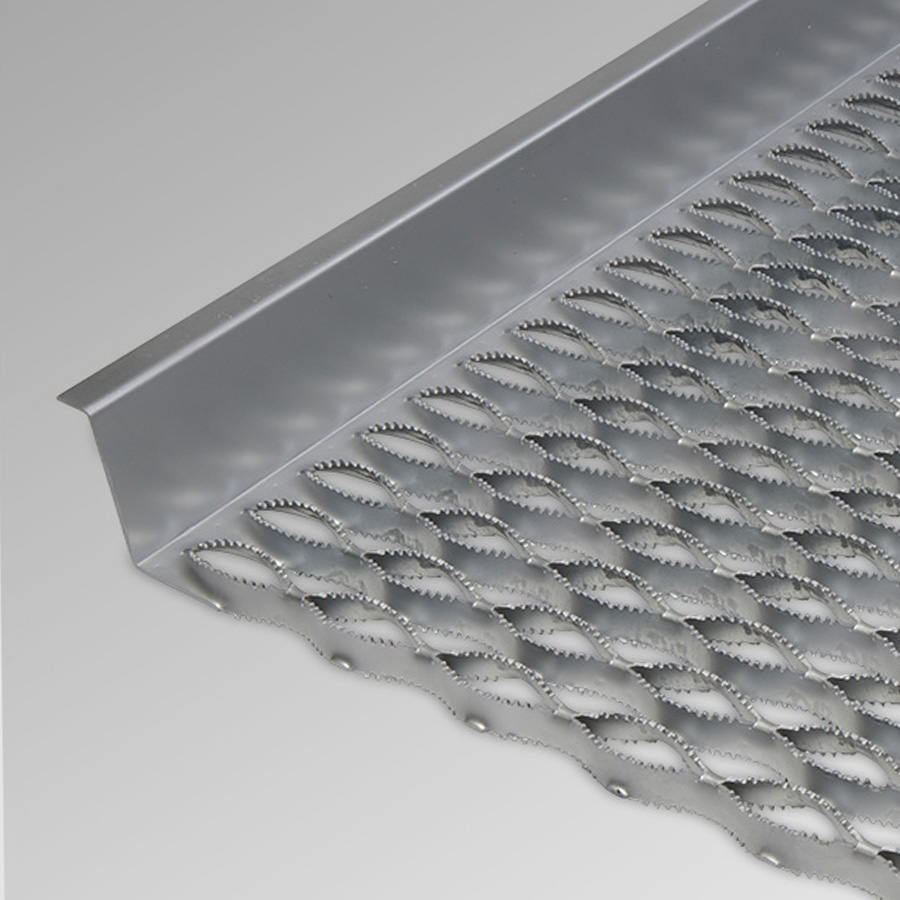

- Serrated Grating:

- Serrated edges provide maximum slip resistance, even in oily or icy conditions.

3. Dimensions

- Plank Widths:

- Typically range from 4 inches (100 mm) para 36 inches (900 mm).

- Comprimento:

- Common lengths vary from 2 feet (600 mm) para 24 feet (7.3 meters), customizable for specific needs.

- Grossura:

- Standard thicknesses are 12 gauge (2.5 mm) para 16 gauge (1.5 mm).

4. Load Capacities

- Safety grating is designed to handle pedestrian traffic and light-to-moderate loads, with load capacities depending on material, thickness, and support spacing.

5. Coatings and Finishes

- Galvanized Steel:

- Zinc-coated for rust prevention and outdoor durability.

- Powder-Coated:

- Available in various colors for aesthetic or functional purposes.

- Mill Finish:

- Unfinished for indoor or non-corrosive environments.

6. Compliance with Standards

- OSHA (Occupational Safety and Health Administration): Meets slip-resistance and safety regulations.

- ASTM Standards: Ensures material and structural quality.

- ISO 9001: Certified manufacturing processes.

Manufacturing Processes

1. Stamping

- Raised patterns (e.g., diamonds or perforations) are stamped into the metal sheet, creating a non-slip surface.

2. Welding

- For certain applications, planks or sections may be welded to form larger grating panels.

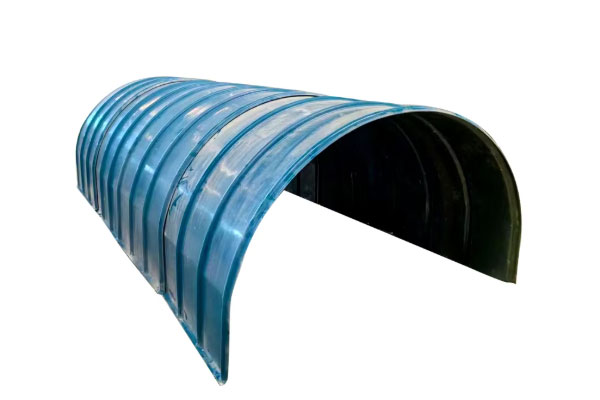

3. Cutting and Forming

- Grating panels are cut and shaped to meet specific dimensions and configurations, including curves or complex designs.

Types of Safety Grating

1. Plank Grating

- Long, narrow panels with a perforated surface, suitable for walkways and platforms.

2. Channel Grating

- Features a "C" or "U" channel profile, providing added strength and rigidity.

3. Ladder Rungs

- Designed for use on ladders, offering slip-resistant surfaces for climbing.

4. Stair Treads

- Pre-cut and pre-formed treads for stairs, often with nosing for added safety.

5. Expanded Metal Grating

- A sheet of metal cut and stretched to form a diamond-shaped mesh pattern, providing traction and drainage.

Applications of Safety Grating

-

Industrial Walkways:

- Ensures safe footing in manufacturing facilities, oil rigs, and refineries.

-

Degraus de escada:

- Prevents slips and falls on stairs in both indoor and outdoor environments.

-

Maintenance Platforms:

- Used in facilities requiring safe access to machinery and equipment.

-

Mezzanines:

- Provides safe, elevated working surfaces with proper ventilation and drainage.

-

Loading Docks and Ramps:

- Ideal for areas exposed to wet or slippery conditions.

-

Agricultural and Food Processing:

- Stainless steel options resist corrosion and contamination in hygienic environments.

-

Architectural Applications:

- Used in decorative designs for facades, screens, or public walkways.

Advantages of Safety Grating

- Segurança aprimorada: Minimizes the risk of slips, trips, and falls.

- Efficient Drainage and Ventilation: Reduces pooling of liquids and buildup of debris.

- Durable and Long-Lasting: Withstands heavy use and harsh conditions.

- Facilidade de instalação: Lightweight and easy to cut, transport, and install.

- Personalizável: Available in a range of sizes, materials, and finishes to suit specific needs.

Installation Guidelines

-

Preparation:

- Ensure the support structure is stable and capable of bearing the anticipated loads.

- Verify measurements and ensure proper alignment.

-

Fastening:

- Use bolts, clips, or welding to secure the grating.

- Ensure fasteners are corrosion-resistant, especially in outdoor or marine environments.

-

Alignment:

- Align grating panels to ensure even load distribution and aesthetic consistency.

-

Inspeção:

- Check for sharp edges or burrs that could pose hazards during installation.

Safety Grating in Various Environments

-

Wet or Oily Conditions:

- Serrated or diamond-pattern grating provides excellent traction.

-

Aplicações ao ar livre:

- Galvanized or stainless steel grating resists rust and corrosion from weather exposure.

-

High-Traffic Areas:

- Durable grating ensures long-lasting performance despite constant use.

Maintenance Tips

- Regular Cleaning:

- Remove debris, oil, or dirt to maintain slip resistance.

- Inspeção:

- Periodically inspect for signs of wear, corrosion, or damage.

- Replacement:

- Replace worn or damaged panels to ensure continued safety.

Conclusão

Safety grating is an essential component in environments where secure footing and worker safety are critical. With its variety of types, materials, and surface patterns, it offers tailored solutions for diverse applications. By choosing the right specifications and maintaining proper installation practices, safety grating ensures long-term functionality, safety, and cost-efficiency.

Outros produtos relacionados