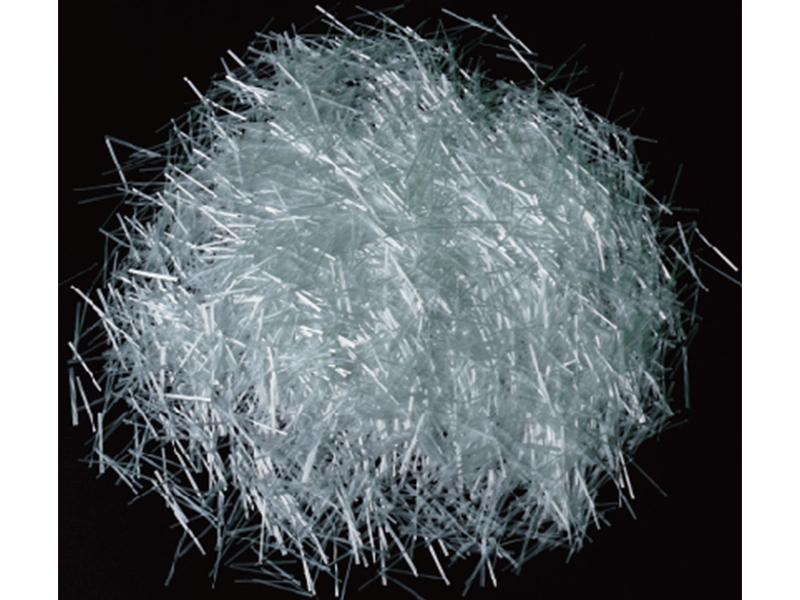

Spraying roving, also known as chopped strand roving, is a fiberglass reinforcement material primarily used in spray-up processes. It is composed of continuous strands of E-glass (electrical-grade glass) filaments, coated with a sizing compatible with polyester, vinyl ester, epoxy, or polyurethane resins. This type of roving is designed for use in open-mold spray-up applications where the roving is chopped and simultaneously deposited with resin using a spray gun.

Introdução ao desempenho do produto

Spraying roving is known for its fast wet-out, excellent dispersion, and strong adhesion to the resin matrix, making it an ideal reinforcement in the fabrication of composite products such as bathtubs, boats, automotive parts, storage tanks, and various construction components.

2. Product Features and Characteristics

-

Compatibility: Spraying roving is available with different sizing systems to ensure compatibility with a wide range of resins, including:

-

Unsaturated polyester (UP)

-

Vinyl ester (VE)

-

Epoxy (EP)

-

Phenolic and polyurethane systems

-

-

Even Dispersion: Designed to provide uniform chopping and easy dispersion of strands with minimal fuzz generation.

-

High Integrity: Offers excellent strand integrity and resistance to fuzzing and static buildup during processing.

-

Fast Wet-Out: Enables quick resin impregnation, improving production efficiency and reducing air entrapment.

-

Excellent Mechanical Properties: Provides high tensile, flexural, and impact strength in finished parts.

-

Resistência à corrosão: Like all fiberglass products, spraying roving is highly resistant to chemical corrosion, making it suitable for marine and chemical industry applications.

-

Dimensional Stability: Resistant to shrinkage, warping, or deformation under heat and moisture.

3. Aplicações

Spraying roving is widely used across multiple industries. Below are key applications:

3.1 Marine Industry

-

Boat hulls and decks

-

Canoes and kayaks

-

Personal watercraft components

3.2 Sanitary Ware

-

Bathtubs

-

Shower stalls

-

Washbasins

-

Water tanks

3.3 Automotive

-

Body panels

-

Hoods

-

Interior components

-

Truck parts

3.4 Construction and Infrastructure

-

Wall panels

-

Corrugated sheets

-

Roofing components

-

Pipe liners and covers

3.5 Industrial Equipment

-

Chemical storage tanks

-

Ducts and hoods

-

Machine housings

3.6 Recreational Goods

-

Surfboards

-

Water slides

-

Playground equipment

4. Manufacturing Process: Spray-Up Technology

Spraying roving is primarily applied using the spray-up technique, a widely used open-mold process. Here’s how it works:

4.1 Equipment

-

Spray gun fitted with a chopper

-

Resin reservoir and pump system

-

Compressed air source

-

Catalyst injection system

-

Open mold (typically coated with a gel coat)

4.2 Process Steps

-

Mold Preparation: Apply a mold release agent and gel coat.

-

Chopping and Spraying: The roving is fed through the chopper and sprayed simultaneously with resin and catalyst.

-

Rolling and Compaction: A roller is used to compact the laminate, removing air bubbles and ensuring uniform thickness.

-

Cura: The part is left to cure at room temperature or under heat, depending on the resin system.

-

Demolding and Trimming: Once fully cured, the part is removed from the mold and trimmed as required.

5. Advantages of Spraying Roving

-

Ease of Use: Simplifies the reinforcement process by integrating chopping and deposition.

-

Custo-beneficio: Reduces labor and time compared to hand lay-up methods.

-

High Productivity: Enables faster build-up of laminate layers.

-

Design Flexibility: Suitable for complex shapes and large surface areas.

-

Improved Resin Control: Optimized resin-to-glass ratio contributes to part performance and weight optimization.

-

Surface Finish Quality: Compatible with gel coats for excellent surface aesthetics.

6. Technical Data Sheet (TDS)

Nome do produto: Spraying Roving

Glass Type: E-glass

Form: Continuous strand roving for spray-up

6.1 Physical Properties

| Propriedade | Typical Value |

|---|---|

| Diâmetro do Filamento | 13–17 microns |

| Linear Density (Tex) | 2400, 3000, 4800 |

| Moisture Content | ≤ 0.10% |

| Size Content | 0.8–1.2% (depending on compatibility) |

| Capacidade de corte | Excelente |

| Dispersion | Uniform |

| Fuzz Level | Very Low |

6.2 Mechanical Properties

| Propriedade | Typical Value |

|---|---|

| Resistência à tracção | > 1800 MPa |

| Tensile Modulus | > 72 GPa |

| Resistência à flexão | > 1200 MPa (in composite) |

| Resistência ao impacto | Alto |

| Elongation at Break | 2.5–3.0% |

6.3 Compatibility Options

| Resin Type | Compatible Sizing Code |

|---|---|

| Unsaturated Polyester | UP Series |

| Éster vinílico | VE Series |

| Epoxy | EP Series |

| Polyurethane | PU Series |

7. Packaging & Storage

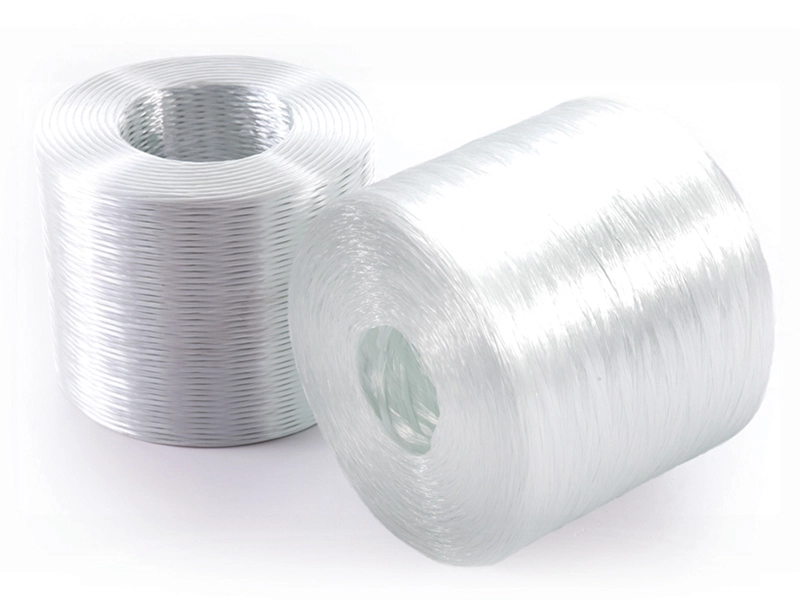

Embalagem

-

Roving is wound onto cylindrical cardboard bobbins or pancakes.

-

Each roll is typically 15–25 kg depending on tex.

-

Rolls are shrink-wrapped and packed in cardboard boxes or pallets.

-

Pallets are stretch-wrapped for moisture protection.

Armazenar

-

Store in a dry, cool, and well-ventilated area.

-

Recommended temperature: 15–35°C

-

Relative humidity: < 65%

-

Avoid direct sunlight and contact with moisture.

Shelf Life: 12 months from the date of manufacture when stored under optimal conditions.

8. Handling & Processing Guidelines

-

Unwinding: Use a creel system to maintain tension and prevent fuzzing or tangling.

-

Cutting: Ensure the chopper blades are sharp to maintain uniform strand lengths.

-

Pressão do ar: Optimize air pressure in spray guns to ensure even spray patterns.

-

Roller Application: Use rollers immediately after spraying to improve consolidation and remove trapped air.

9. Safety and Environmental Information

Health and Safety

-

Spraying roving is a non-hazardous product under normal conditions.

-

Mechanical irritation to skin, eyes, and respiratory tract may occur during handling.

-

Use personal protective equipment (PPE) such as:

-

Gloves

-

Goggles

-

Dust masks or respirators

-

First Aid Measures

-

Skin Contact: Wash with soap and water.

-

Eye Contact: Rinse thoroughly with water.

-

Inhalation: Move to fresh air and seek medical advice if symptoms persist.

Environmental Impact

-

Non-toxic and non-reactive under normal disposal.

-

Complies with environmental regulations for industrial fiberglass products.

-

Recyclable in some processes or can be safely landfilled in accordance with local laws.

10. Customization and Technical Support

Manufacturers often provide custom spraying rovings tailored to specific production needs. Options include:

-

Custom tex values

-

Specialized sizing agents for unique resins

-

Color-coded or tracer filaments for identification

-

Eco-friendly or reduced-emission formulations

Technical support is typically offered to assist in optimizing spray-up parameters and improving part quality, with services including:

-

On-site technical consultation

-

Spray equipment calibration

-

Defect analysis and troubleshooting

-

Training and education on best practices

11. Conclusion

Spraying roving is an indispensable material in the composites industry, valued for its ease of use, versatility, and performance. Whether you're manufacturing boats, bathtubs, automotive components, or construction panels, spraying roving provides a cost-efficient and high-strength reinforcement solution that adapts to complex shapes and production environments.

By choosing the appropriate tex, sizing, and spray-up parameters, manufacturers can optimize productivity while delivering durable, high-quality composite parts. With advancements in sizing chemistry and application methods, spraying roving continues to evolve, offering greater performance, compatibility, and sustainability for modern composite applications.

Spraying roving

aplicativo

Automotivo / Bens de Consumo e Equipamentos Empresariais / Esporte e Lazer / Elétrica e Eletrônica / Edificação e Construção / Infraestrutura

Tipo de vidro:

E

Tipo de dimensionamento:

Silano

Diâmetro típico do filamento (μm):

13

Densidade linear típica (tex):

2000

Exemplo :

EDR13-2000-910A

Perguntas frequentes

P:

Você é uma fábrica? Onde você está localizado?

A :

Somos fabricantes de grades de FRP e perfis pultrudados, comerciantes de materiais de fios de FRP. Somos o maior distribuidor da China Jushi Co. Também vendemos produtos de vários fabricantes de fios FRP. Estamos em Anhui, China.

P:

Quais informações são recomendadas para a consulta?

A :

1. Qual texto você precisa? 2. Para que aplicativo você o usa? Ou a tecnologia é tecelagem, pultrusão ou enrolamento? 3. Quantas quantidades você precisa? 4. Com que resina você combina? Resina de poliéster ou resina epóxi? 5. Você precisa de preço FOB ou CIF, se for CIF, informe-nos sua porta.

P:

Qual é o MOQ?

A :

Geralmente 1 tonelada

P:

Pacote e envio

A :

Pacote normal: caixa (incluído no preço unitário) Pacote especial: precisa cobrar de acordo com a situação real. Envio normal: seu encaminhamento de frete indicado.

P:

Quando posso oferecer?

A :

Geralmente citamos dentro de 24 horas após recebermos sua consulta. Se você é muito urgente para obter o preço, ligue para nós ou diga-nos em seu e-mail, para que possamos responder com prioridade.

P:

Como você cobra as taxas da amostra?

A :

Se você precisar de amostras de nosso estoque, podemos fornecer gratuitamente, mas você precisa pagar o frete. Se você precisar de um tamanho especial, cobraremos a taxa de fabricação de amostra, que é reembolsável quando você fizer um pedido.

P:

qual é o seu tempo de entrega para a produção?

A :

Se tivermos estoque, podemos entregar em 7 dias; se sem estoque, precisa de 7 a 15 dias!

Outros produtos relacionados