Product performance introduction

Introduction

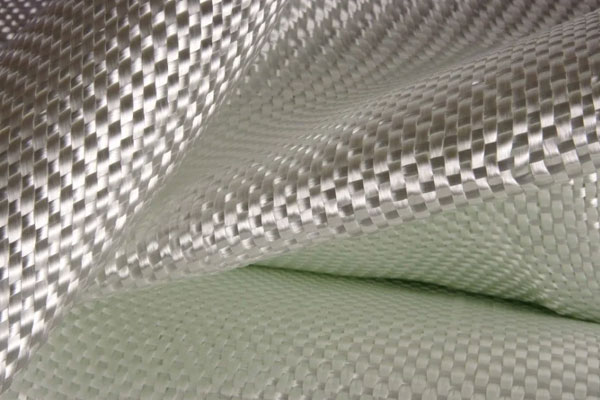

Riveted grating is a specialized form of steel grating characterized by its exceptional strength and durability. Unlike welded or press-locked grating, riveted grating is constructed by riveting bearing bars to reticulated cross bars, creating a robust and stable structure. This construction method makes it suitable for heavy-duty applications, particularly in environments with significant loads and impact forces.

This document covers the detailed specifications, models, dimensions, and other essential information regarding riveted grating.

1. Specifications of Riveted Grating

Material Composition

-

Carbon Steel: Provides excellent strength and durability for heavy-load applications.

-

Stainless Steel: Offers superior corrosion resistance, ideal for corrosive and marine environments.

-

Galvanized Steel: Hot-dip galvanized for added corrosion protection.

-

Aluminum: Lightweight, corrosion-resistant, and suitable for applications requiring minimal weight.

Surface Treatment Options

-

Hot-Dip Galvanizing: The most common treatment to ensure corrosion resistance and extended service life.

-

Powder Coating: Adds a protective layer with various color options.

-

Mill Finish: Offers a plain steel finish, suitable for indoor applications.

-

Paint Coating: Provides additional protection and aesthetic customization.

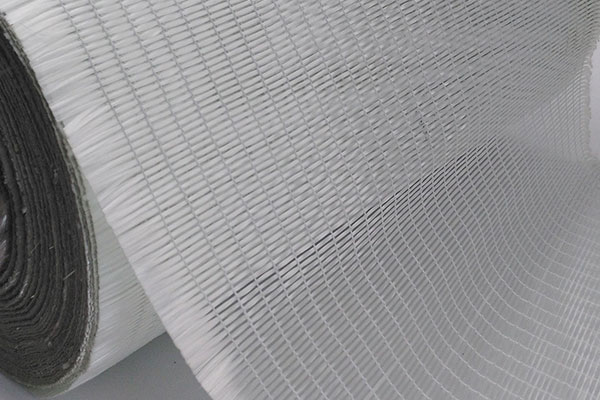

Riveting Process

-

Bearing bars and cross bars are riveted together using hydraulic or mechanical riveting machines.

-

This creates a secure connection, enhancing load distribution and durability.

2. Models and Types

Based on Bearing Bar Profile

-

Flat Bar Riveted Grating: Offers maximum load-bearing capacity.

-

I-Bar Riveted Grating: Provides a lighter structure with reduced material usage.

-

Serrated Bar Riveted Grating: Enhances slip resistance for wet or slippery environments.

Based on Load Capacity

-

Standard Duty Riveted Grating: Suitable for pedestrian traffic and light vehicle loads.

-

Heavy Duty Riveted Grating: Designed for industrial and vehicular applications.

Based on Application

-

Industrial Riveted Grating: Used in plants, factories, and warehouses.

-

Bridge Deck Grating: Supports heavy vehicular loads on bridges and walkways.

-

Trench Cover Grating: Commonly used in drainage systems.

3. Dimensions

Bearing Bar Dimensions

-

Thickness: Typically ranges from 3 mm to 12 mm.

-

Height: Common heights include 25 mm, 30 mm, 40 mm, and 50 mm.

-

Width: Varies from 20 mm to 150 mm, depending on the application.

Cross Bar Dimensions

-

Width: Usually 5 mm to 10 mm.

-

Spacing: Standard spacing ranges from 50 mm to 100 mm.

Panel Sizes

-

Standard Panel: 1,000 mm x 6,000 mm.

-

Custom Sizes: Available upon request for specific projects.

4. Design Considerations

-

Load Requirements: Ensure the chosen bearing bar thickness and spacing can support the anticipated load.

-

Corrosion Resistance: For outdoor or corrosive environments, galvanized or stainless steel is recommended.

-

Slip Resistance: Serrated bearing bars improve safety in areas exposed to moisture.

-

Aesthetic Appeal: Powder-coated or painted riveted grating can enhance visual appeal.

5. Applications of Riveted Grating

-

Industrial Platforms: Provides durable flooring for heavy machinery areas.

-

Bridge Decking: Supports vehicular and pedestrian traffic.

-

Catwalks and Walkways: Ensures safety in elevated environments.

-

Trench Covers and Drainage Systems: Allows efficient water drainage.

-

Marine and Offshore Structures: Resistant to harsh marine conditions.

Conclusion

Riveted grating is a robust and reliable option for demanding applications. Its superior strength, durability, and load-bearing capacity make it suitable for industrial, transportation, and infrastructure projects. By selecting the appropriate material, surface treatment, and dimensions, users can ensure optimal performance and longevity in their applications.

Riveted Grating

Series :

Proxy Products >application

Industrial Platforms: Provides durable flooring for heavy machinery areas. Bridge Decking: Supports vehicular and pedestrian traffic. Catwalks and Walkways: Ensures safety in elevated environments. Trench Covers and Drainage Systems: Allows efficient water drainage. Marine and Offshore Structures: Resistant to harsh marine conditions.

FAQ

Other related products