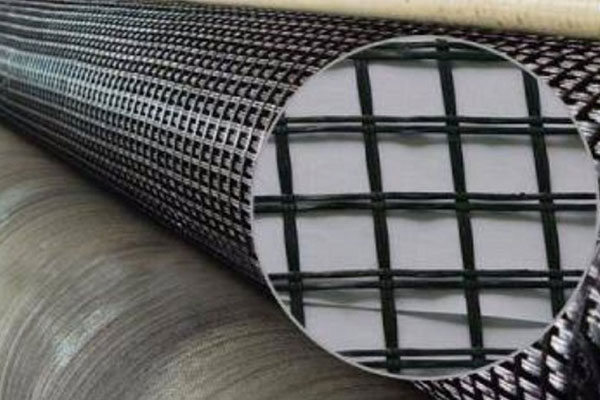

Fiberglass geogrids are advanced materials made from high-strength fiberglass yarns that are woven and coated with a polymer, typically a PVC or epoxy-based resin. These geogrids offer superior tensile strength and long-lasting durability, making them ideal for a variety of civil engineering applications. As a geosynthetic product, fiberglass geogrids are primarily used to reinforce soil, provide stability to unbound materials, and improve load-bearing capacity in various infrastructure projects.

การแนะนำประสิทธิภาพของผลิตภัณฑ์

The use of fiberglass in geogrids allows for enhanced dimensional stability, resistance to deformation, and excellent durability under both mechanical and environmental stresses. These geogrids can significantly improve the performance of roadways, railway embankments, retaining walls, and other soil stabilization applications.

2. Composition and Structure of Fiberglass Geogrids

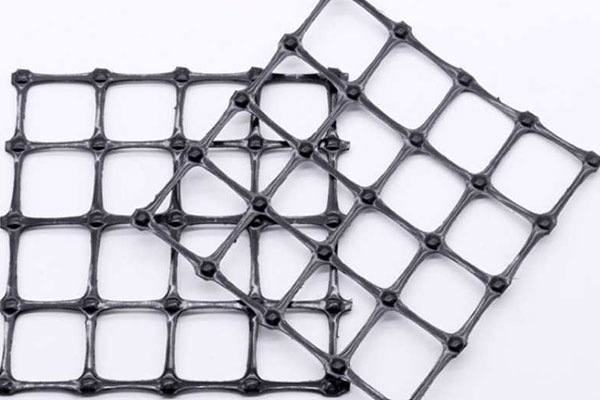

Fiberglass geogrids are made from a core of fiberglass filaments that are woven into a grid pattern. The filaments are coated with a polymeric resin, which provides them with UV resistance, chemical resistance, and waterproofing. The grid structure of the geogrid increases its surface area, allowing it to interlock with surrounding soil or aggregate materials. This interlocking mechanism improves soil friction and enhances the overall stability of the structure.

2.1 Materials Used

-

Fiberglass Yarns: High-strength, lightweight, and durable, offering excellent tensile strength.

-

Polymeric Coating (PVC or Epoxy): Provides resistance to environmental degradation, UV rays, and chemicals.

-

Anti-Corrosive Additives: Prevent corrosion from moisture or aggressive environmental factors.

2.2 Manufacturing Process

The process begins with weaving the fiberglass filaments into a grid. After the grid structure is formed, a polymer coating is applied to ensure the geogrid is resistant to environmental stresses, including UV exposure, extreme temperatures, and aggressive chemicals. This coating ensures that the geogrid performs well under long-term exposure to outdoor conditions.

3. Types of Fiberglass Geogrids

Fiberglass geogrids are typically available in different configurations based on their intended use and the strength requirements of the project. The primary types include:

3.1 Uniaxial Fiberglass Geogrid

-

แอปพลิเคชัน: Primarily used for applications requiring high strength in one direction, such as reinforcement of steep slopes, retaining walls, and embankments.

-

ความแข็งแกร่ง: Provides excellent tensile strength in the longitudinal direction.

-

โครงสร้าง: The geogrid is oriented such that its high-strength axis is aligned with the expected directional loads.

3.2 Biaxial Fiberglass Geogrid

-

แอปพลิเคชัน: Used for general reinforcement applications like subgrade stabilization, base course reinforcement, and road construction.

-

ความแข็งแกร่ง: Equal strength in both the longitudinal and transverse directions, making it ideal for applications where the load is distributed in multiple directions.

-

โครงสร้าง: The grid has uniform strength in both directions.

4. Key Features and Benefits of Fiberglass Geogrids

4.1 High Tensile Strength

Fiberglass geogrids are engineered to provide exceptional tensile strength, even under heavy loads. This characteristic makes them ideal for applications where soil reinforcement is critical, such as in roadways and embankments.

4.2 Excellent Dimensional Stability

Due to the unique construction and use of fiberglass, these geogrids maintain their shape and size under stress, preventing deformation or elongation during usage.

4.3 Durability and Longevity

The polymeric coating protects fiberglass geogrids from environmental degradation, including UV rays, moisture, and temperature fluctuations. This results in a long lifespan (typically 50+ years) when properly installed and maintained.

4.4 Resistance to Chemicals

Fiberglass geogrids are resistant to a wide range of chemicals, including acids, alkalis, and organic solvents, making them suitable for use in challenging industrial and waste containment applications.

4.5 Lightweight and Easy Installation

Fiberglass geogrids are lightweight compared to traditional reinforcement materials, which simplifies handling and reduces labor costs during installation. They can be rolled out and cut easily on-site.

4.6 Environmentally Friendly

Fiberglass geogrids help reduce the environmental impact by lowering the need for large quantities of gravel, asphalt, and other materials. They improve the efficiency of construction projects, which can result in less waste and fewer resources consumed.

5. Applications of Fiberglass Geogrids

Fiberglass geogrids are widely used in various industries, particularly in the construction and infrastructure sectors. Below are some of the most common applications:

5.1 Road and Pavement Reinforcement

Fiberglass geogrids are widely used in road construction and pavement reinforcement. They provide soil stabilization, reduce the required thickness of the base layers, and help prevent pavement cracking and rutting.

5.2 Embankment Stabilization

Geogrids reinforce embankments by distributing loads over a wider area. This prevents slope failure and provides long-term stability, especially in areas subject to seismic activity or heavy rain.

5.3 Retaining Walls

Fiberglass geogrids are used to construct reinforced retaining walls by connecting the soil with the geogrid. They help the wall withstand lateral pressure from the soil, improving its stability and reducing the risk of wall failure.

5.4 Slope Stabilization

In slope stabilization applications, fiberglass geogrids are used to prevent soil erosion and provide structural support for steep slopes. The geogrid enhances the friction between soil particles and helps prevent sliding or shifting.

5.5 Railway Ballast Stabilization

Fiberglass geogrids are used to stabilize railway ballast by preventing the migration of fine particles and increasing the durability of the track structure. This improves load distribution and prevents settlement of the ballast layer.

5.6 Waste Containment and Landfills

Due to their chemical resistance, fiberglass geogrids are often employed in landfill and waste containment applications. They help prevent the movement of waste materials and enhance the stability of landfill surfaces.

6. Technical Data Sheet (TDS)

Below is a typical Technical Data Sheet (TDS) for fiberglass geogrids. The values can vary depending on the manufacturer and specific product specifications.

6.1 Technical Specifications for Uniaxial Fiberglass Geogrid

| คุณสมบัติ | วิธีทดสอบ | Typical Value |

|---|---|---|

| วัสดุ | - | Fiberglass (with polymeric coating) |

| Tensile Strength (MD) | ASTM D6637 | 100 – 250 kN/m |

| Elongation at Break | ASTM D6637 | ≤3% |

| Tensile Modulus (MD) | ASTM D6637 | 5,000 – 15,000 MPa |

| UV Resistance (500 hrs) | ASTM D4355 | ≥90% of initial strength |

| Nominal Aperture Size | - | 25 mm x 25 mm (typical) |

| Roll Width | - | 1 m – 4 m |

| Roll Length | - | 30 m – 100 m |

| Junction Strength | ASTM D7737 | ≥90% |

6.2 Technical Specifications for Biaxial Fiberglass Geogrid

| คุณสมบัติ | วิธีทดสอบ | Typical Value |

|---|---|---|

| วัสดุ | - | Fiberglass (with polymeric coating) |

| Tensile Strength (MD/CD) | ASTM D6637 | 50 – 150 kN/m |

| Elongation at Break | ASTM D6637 | ≤5% |

| Tensile Modulus (MD/CD) | ASTM D6637 | 5,000 – 10,000 MPa |

| UV Resistance (500 hrs) | ASTM D4355 | ≥90% of initial strength |

| Nominal Aperture Size | - | 30 mm x 30 mm (typical) |

| Roll Width | - | 2 m – 4 m |

| Roll Length | - | 30 m – 75 m |

| Junction Strength | ASTM D7737 | ≥95% |

7. Installation Guidelines

7.1 Site Preparation

-

Clear the area of debris, organic material, and sharp objects that could damage the geogrid.

-

Ensure that the subgrade is properly compacted and level to provide a solid base for the geogrid installation.

7.2 Geogrid Installation

-

Unroll the geogrid along the prepared surface. If using multiple rolls, ensure that adjacent rolls overlap by at least 30–50 cm to provide continuous reinforcement.

-

For uniaxial geogrids, ensure the geogrid's high-strength direction aligns with the direction of expected load.

7.3 Backfill and Compaction

-

Place the fill material over the geogrid in layers, making sure not to displace the geogrid during the backfilling process.

-

Compact the fill material using appropriate equipment (vibratory roller or other compacting machinery).

8. Conclusion

Fiberglass geogrids are an essential material for improving the stability and performance of infrastructure projects that involve soil and aggregate stabilization. With their high tensile strength, excellent durability, and resistance to environmental stresses, fiberglass geogrids provide significant advantages in a wide range of civil engineering applications.

Fiberglass Geogrid

ชุด :

สินค้า >แอปพลิเคชัน

Fiberglass geogrids are primarily used in: Roadway and pavement reinforcement Slope stabilization Retaining walls Railway ballast stabilization Embankment and landfill stabilization Waste containment

ชื่อแบรนด์ :

ทีเอฟคอมโพสิต

ชื่อผลิตภัณฑ์ :

Fiberglass Geogrid

คำถามที่พบบ่อย

ถาม :

What is the difference between fiberglass geogrids and other types of geogrids?

ตอบ :

Fiberglass geogrids are made from fiberglass yarns, which offer superior tensile strength, high dimensional stability, and resistance to environmental stresses. Compared to other geogrids, such as polymer-based ones, fiberglass geogrids provide excellent performance in high-load and long-term applications. Their polymer coating offers resistance to UV degradation, making them suitable for outdoor and exposed conditions.

ถาม :

What are the advantages of fiberglass geogrids?

ตอบ :

High tensile strength: Fiberglass geogrids are known for their excellent load-bearing capacity, which makes them ideal for applications where high strength is needed. Dimensional stability: They maintain their shape and size even under heavy loads, reducing the risk of deformation over time. Durability: The polymer coating ensures long-lasting performance, even under extreme weather and UV exposure. Chemical resistance: They are resistant to a variety of chemicals, including acids, alkalis, and hydrocarbons. Ease of installation: Lightweight and easy to handle, fiberglass geogrids simplify transportation and reduce installation costs.

ถาม :

How do fiberglass geogrids improve soil stabilization?

ตอบ :

Fiberglass geogrids improve soil stabilization by providing a reinforcement mechanism that interlocks with surrounding soil particles. This interlocking effect enhances the frictional resistance between the soil and geogrid, distributing loads more evenly across the surface. As a result, the bearing capacity of the soil is significantly increased, reducing the likelihood of settlement or failure.

ถาม :

Are fiberglass geogrids resistant to UV rays?

ตอบ :

Yes, fiberglass geogrids are coated with a polymeric resin (such as PVC or epoxy), which provides UV resistance. This ensures that the geogrid maintains its strength and durability even when exposed to sunlight for extended periods, making it suitable for outdoor applications.

ถาม :

How long do fiberglass geogrids last?

ตอบ :

Fiberglass geogrids have a long service life, typically ranging from 50 to 100 years. The lifespan depends on factors such as installation quality, environmental conditions, and the type of reinforcement required. With proper installation and care, fiberglass geogrids can provide long-term stability in infrastructure projects.

ถาม :

Can fiberglass geogrids be used in extreme climates?

ตอบ :

Yes, fiberglass geogrids are designed to perform well in a wide range of climates, from hot, dry environments to freezing, cold conditions. The polymer coating helps protect the fiberglass core from moisture, temperature fluctuations, and other environmental stresses.

ถาม :

How are fiberglass geogrids installed?

ตอบ :

Fiberglass geogrids are installed by unrolling them over the prepared surface and ensuring proper alignment. When used for base reinforcement, multiple layers may be installed with the grid overlapping by 30-50 cm. After installation, fill material is placed over the geogrid, and the area is compacted to secure the geogrid in place.

ถาม :

Can fiberglass geogrids be used for slope reinforcement?

ตอบ :

Yes, fiberglass geogrids are highly effective in slope reinforcement. They help prevent soil erosion and increase the shear strength of the slope, thus providing stability and preventing failure. The geogrid works by reinforcing the soil and providing tensile strength to prevent sliding or shifting of materials.

สินค้าอื่นๆที่เกี่ยวข้อง