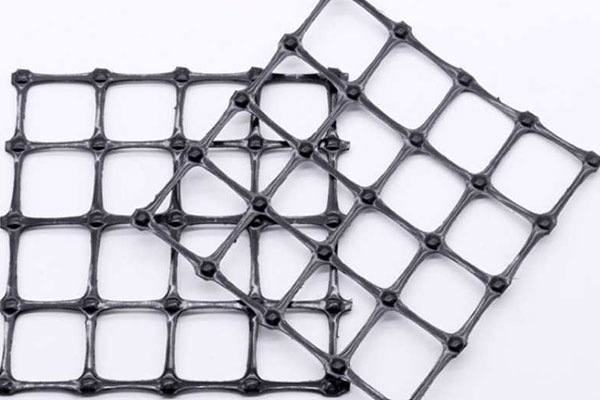

Plastic geogrids are a type of geosynthetic material primarily used in soil reinforcement applications. These grid-like structures are made from polymers such as high-density polyethylene (HDPE) or polypropylene (PP), and are known for their high tensile strength, chemical resistance, and durability under harsh environmental conditions.

การแนะนำประสิทธิภาพของผลิตภัณฑ์

They are designed to improve the mechanical properties of soil and other construction materials by distributing loads over a wider area, increasing stability, and reducing settlement. Plastic geogrids are commonly used in civil engineering, infrastructure development, and environmental remediation projects.

2. Product Types

2.1 Uniaxial Geogrid

-

Stretched in one direction, typically the longitudinal (machine) direction.

-

High tensile strength in one axis.

-

Applications: Retaining walls, embankment reinforcement, steep slopes.

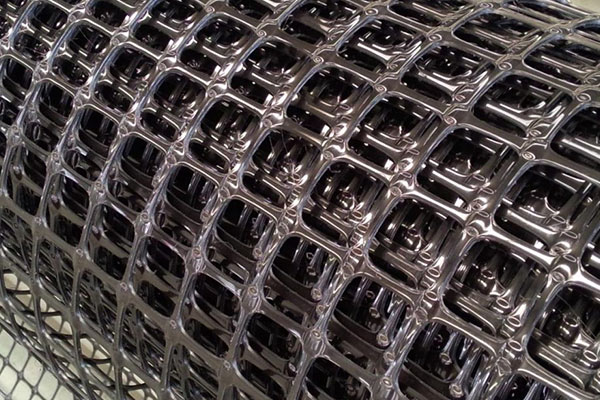

2.2 Biaxial Geogrid

-

Stretched in both longitudinal and transverse directions.

-

Equal strength in both directions.

-

Applications: Road base reinforcement, subgrade stabilization, airport runways.

2.3 Triaxial Geogrid

-

Manufactured with a triangular aperture design.

-

Multi-directional strength with optimized load distribution.

-

Applications: Railway ballast stabilization, embankments, high-stress zones.

3. Raw Material Composition

-

Polypropylene (PP): Light-weight, chemically resistant, high tensile strength.

-

High-Density Polyethylene (HDPE): Excellent durability, environmental resistance, and flexibility.

-

UV Stabilizers: Incorporated to improve outdoor performance and longevity.

-

Carbon Black: Added to enhance UV resistance.

4. Product Features

-

ความต้านทานแรงดึงสูง: Ensures excellent load-bearing capacity.

-

Dimensional Stability: Maintains shape and structure under stress.

-

ทนต่อสารเคมี: Resistant to acids, alkalis, and organic solvents.

-

Thermal Stability: Operates effectively in a wide temperature range.

-

Long Lifespan: Up to 50 years depending on installation conditions.

-

ติดตั้งง่าย: Lightweight, rollable, and flexible.

-

Sustainable: Reduces material requirements and enhances design efficiency.

5. Applications

-

Highway and road construction

-

Railways and airports

-

Retaining walls

-

Embankments and slopes

-

Landfills and waste containment

-

Coastal and erosion control

-

Mining haul roads

-

Construction site ground stabilization

6. Technical Specifications (TDS)

6.1 Uniaxial Plastic Geogrid (HDPE Based)

| คุณสมบัติ | วิธีทดสอบ | Typical Value |

|---|---|---|

| วัสดุ | - | HDPE |

| Tensile Strength (MD) | ASTM D6637 | 80 – 200 kN/m |

| Elongation at Break | ASTM D6637 | ≤10% |

| Tensile Strength @ 2% Strain | ASTM D6637 | 30 – 50 kN/m |

| Tensile Strength @ 5% Strain | ASTM D6637 | 60 – 120 kN/m |

| Carbon Black Content | ASTM D4218 | ≥2% |

| UV Resistance (500 hrs) | ASTM D4355 | ≥90% Retained Strength |

| Roll Width | - | 1.5 m – 3.9 m |

| Roll Length | - | 30 m – 100 m |

| Aperture Size | - | 20 mm – 60 mm |

6.2 Biaxial Plastic Geogrid (PP Based)

| คุณสมบัติ | วิธีทดสอบ | Typical Value |

|---|---|---|

| วัสดุ | - | Polypropylene (PP) |

| Tensile Strength (MD/CD) | ASTM D6637 | 15 – 50 kN/m |

| Elongation at Break | ASTM D6637 | ≤13% |

| Tensile Strength @ 2% Strain | ASTM D6637 | 8 – 12 kN/m |

| Tensile Strength @ 5% Strain | ASTM D6637 | 18 – 32 kN/m |

| Junction Strength | ASTM D7737 | ≥90% of rib strength |

| Carbon Black Content | ASTM D4218 | ≥2% |

| UV Resistance (500 hrs) | ASTM D4355 | ≥90% Retained Strength |

| Roll Width | - | 3.95 m |

| Roll Length | - | 50 m |

| Aperture Shape | - | สี่เหลี่ยม |

| Aperture Size | - | 30 mm x 30 mm (typical) |

6.3 Triaxial Geogrid

| คุณสมบัติ | วิธีทดสอบ | Typical Value |

|---|---|---|

| วัสดุ | - | HDPE or PP |

| Rib Tensile Strength | ASTM D6637 | ≥40 kN/m |

| Aperture Shape | - | Triangular |

| Rib Thickness | - | 3 mm – 5 mm |

| Junction Efficiency | - | ≥95% |

| Roll Width | - | 3 m – 4 m |

| Roll Length | - | 50 m – 75 m |

| ต้านทานรังสียูวี | ASTM D4355 | ยอดเยี่ยม |

| Service Life | - | ≥50 years (buried) |

7. Advantages of Plastic Geogrid Systems

-

Improved Bearing Capacity: Enhances soil performance in load-bearing applications.

-

Reduces Structural Thickness: Minimizes base course thickness while maintaining performance.

-

Prevents Lateral Spreading: Keeps aggregate materials confined.

-

คุ้มค่า: Reduces long-term maintenance costs and construction material requirements.

-

ประโยชน์ต่อสิ่งแวดล้อม: Reduces carbon footprint through material optimization.

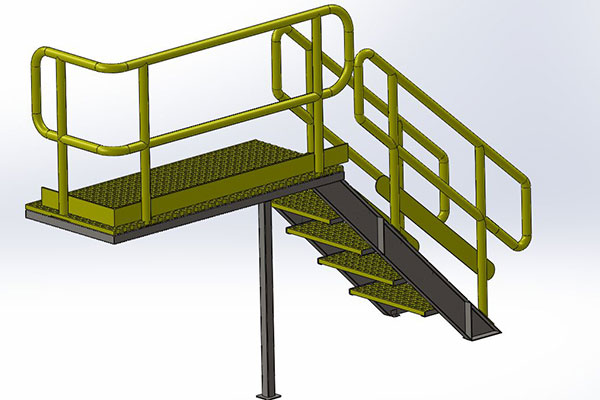

8. Installation Guidelines

Step-by-Step Procedure:

-

การเตรียมสถานที่: Level the subgrade surface and remove debris.

-

Geogrid Deployment: Roll out the geogrid with proper alignment. For uniaxial grids, align with the principal stress direction.

-

Overlap: Overlap adjacent rolls by 30 cm to 60 cm as per design requirements.

-

Anchoring: Use stakes or pins to temporarily hold the geogrid in place.

-

Placement of Fill: Carefully place aggregate fill over the geogrid without displacing it.

-

Compaction: Compact the fill using vibratory rollers.

-

Layering (if needed): For multi-layer systems, repeat steps with new geogrid layers as required.

9. Quality Assurance & Compliance

Plastic geogrids are produced in accordance with the following standards:

-

ASTM D6637 – Tensile strength testing.

-

ASTM D4355 – UV resistance.

-

ISO 9001:2015 – Quality management system.

-

CE Certification – For European market compliance.

-

GRI-GG1, GRI-GG2, GRI-GG4 – Geogrid specifications.

10. Storage and Handling

-

Store rolls on elevated platforms in dry, shaded areas.

-

Avoid prolonged exposure to direct sunlight.

-

Do not stack more than 4 rolls high.

-

Handle with care during transportation to prevent damage.

11. Packaging and Delivery

-

Delivered in rolls, wrapped in polyethylene sheeting or woven fabric.

-

Labeled with product type, dimensions, batch number, and date of manufacture.

-

Available in standard and custom sizes to meet project-specific needs.

12. Summary

Plastic geogrids have become an essential element in modern geotechnical engineering and construction due to their effectiveness, longevity, and cost-saving benefits. Whether used for road reinforcement, wall stabilization, or slope protection, they significantly enhance soil performance, prevent structural failure, and extend infrastructure lifespan.

Plastic Geogrid

ชุด :

สินค้า >แอปพลิเคชัน

Plastic geogrids have become an essential element in modern geotechnical engineering and construction due to their effectiveness, longevity, and cost-saving benefits. Whether used for road reinforcement, wall stabilization, or slope protection, they significantly enhance soil performance, prevent structural failure, and extend infrastructure lifespan.

ชื่อแบรนด์ :

ทีเอฟคอมโพสิต

ชื่อผลิตภัณฑ์ :

Plastic Geogrid

คำถามที่พบบ่อย

ถาม :

What are the types of plastic geogrids?

ตอบ :

Uniaxial Geogrid: Strength in one direction (used for walls and slopes). Biaxial Geogrid: Equal strength in both directions (used for base reinforcement). Triaxial Geogrid: Multi-directional strength (used for areas with varying load directions).

ถาม :

What are the main applications of plastic geogrids?

ตอบ :

Road and highway base reinforcement Retaining walls and embankments Slope stabilization Railway ballast support Airport runways and taxiways Landfill and erosion control

ถาม :

How do geogrids work?

ตอบ :

Geogrids interlock with aggregate or soil particles to improve load distribution, limit lateral movement, and increase the bearing capacity of the subgrade. This reinforcement effect reduces settlement and prevents structural failures.

ถาม :

What is the difference between geogrid and geotextile?

ตอบ :

Geogrids: Grid-like structure with open apertures for interlocking. Geotextiles: Fabric-like materials that separate, filter, or protect but offer limited reinforcement.

ถาม :

What are the advantages of using plastic geogrids?

ตอบ :

Increased structural life Reduced construction material and costs Quick and easy installation Environmentally friendly (reduces carbon footprint) Excellent durability and UV resistance

สินค้าอื่นๆที่เกี่ยวข้อง