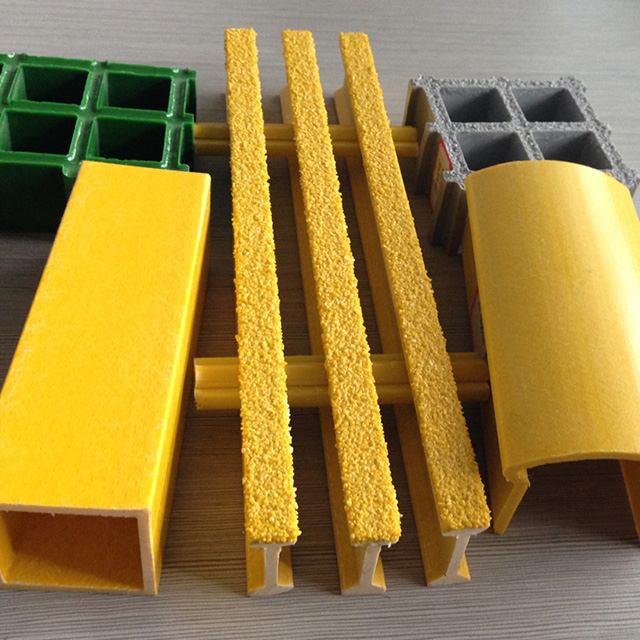

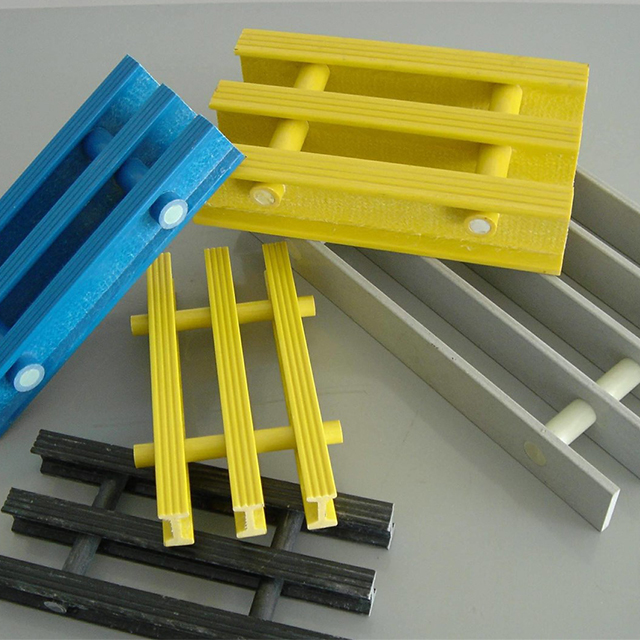

FRP pultruded grating and FRP molded grating are two common types of fiberglass grating, and they have several key differences:

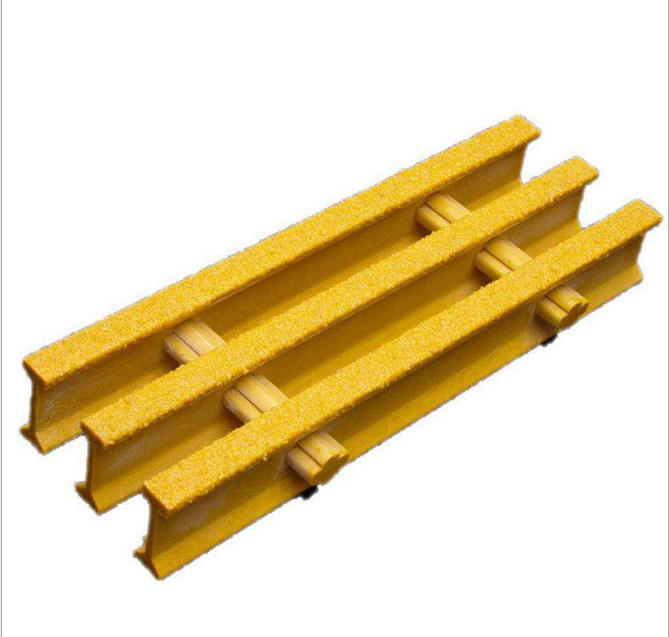

Manufacturing process:

Fiberglass pultruded grating: Pultruded grating is made through the pultrusion process. Continuous fiberglass rovings and mats are impregnated with thermoset resin and pulled through heated molds. The resin is then cured and solidified, forming a strong and durable grating structure.

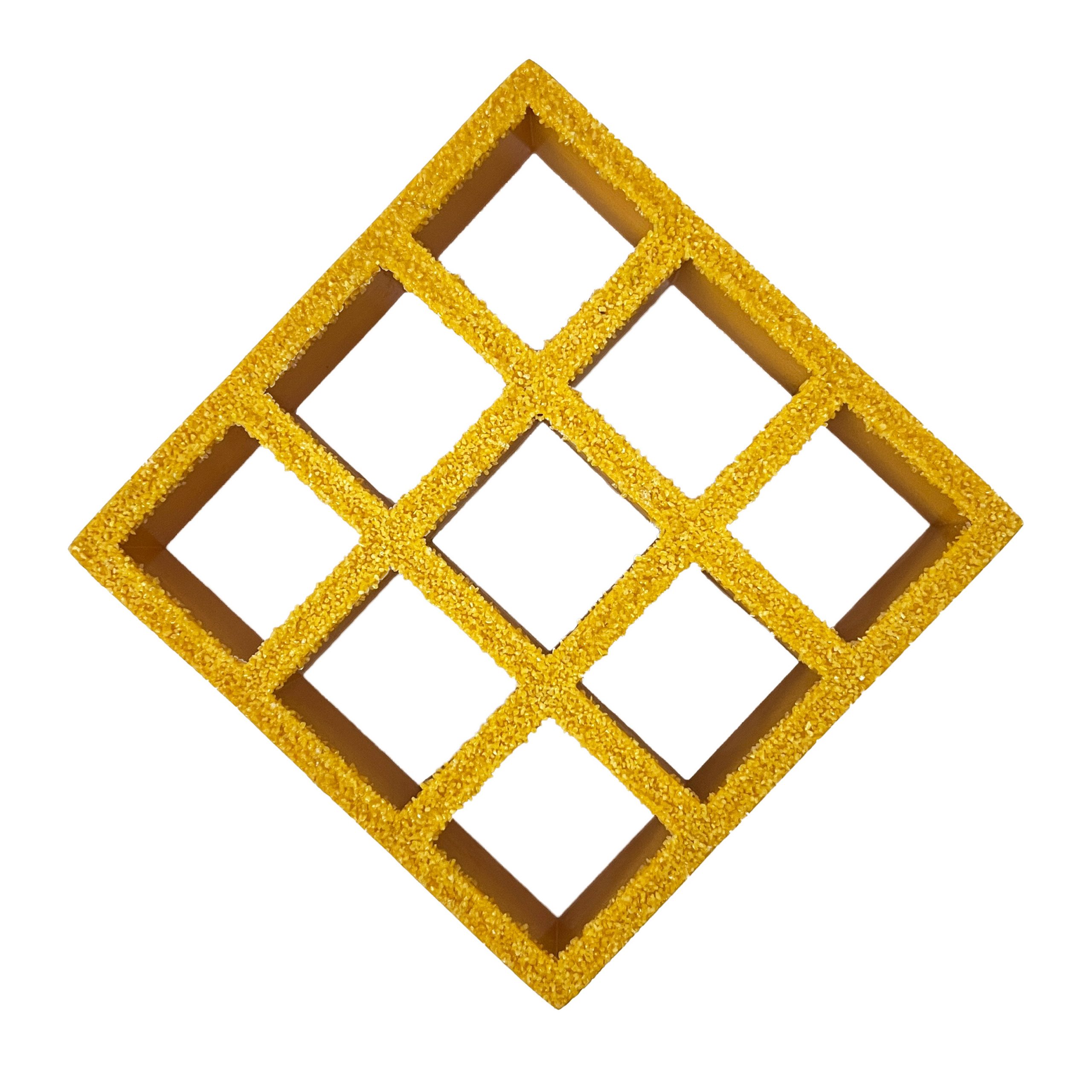

FRP molded grille: Molded grille is manufactured using molding process. Fiberglass rovings and mats are moistened with a resin mixture and then molded in a mold under heat and pressure. The resin cures and solidifies, forming a molded grating panel with a grid-like structure.

Structural features:

FRP pultruded grating: Pultruded grating is composed of load-bearing rods (vertical rods) and horizontal rods (interlocking rods) assembled together. Load-bearing bars provide primary strength and support, while crossbars provide additional structural stability. Pultruded grating panels have a solid surface.

FRP molded grating: Molded grating has a mesh structure with intertwined load-bearing bars and cross bars. The grating is molded into a panel of uniform thickness and opening area. Molded grating panels have an open surface with gaps between the bars.

Strength and load characteristics:

FRP pultruded grating: Compared with molded grating, pultruded grating has higher strength and load-bearing capacity. It has a higher proportion of fiberglass reinforcements, resulting in excellent tensile and flexural strength.

FRP molded grating: Molded grating has good strength and load-bearing capacity; however, due to the interconnected grid structure, its strength is generally lower compared to pultruded grating.

Weight and handling:

FRP pultruded grating: Compared with molded grating, pultruded grating is denser and heavier. Its sturdy construction makes it heavier.

FRP molded grating: Due to its open mesh structure, molded grating is lighter in weight than pultruded grating. This makes operation and installation easier.

Application:

FRP Pultruded Grating: Pultruded Grating is typically used in heavy-duty applications that require high strength, such as industrial floors, walkways, and decks. It is suitable for applications with heavy loads and high rigidity requirements.

FRP molded grating: Molded grating is widely used in situations where drainage, ventilation and medium strength are required, such as walkways, decks, small platforms, etc. People usually choose it because of its light weight and cost-effectiveness.

TFcomposite produces two types of FRP gratings, contact us for the best quote.