The main difference between fiberglass cloth and fiberglass mat lies in their structure and manufacturing process:

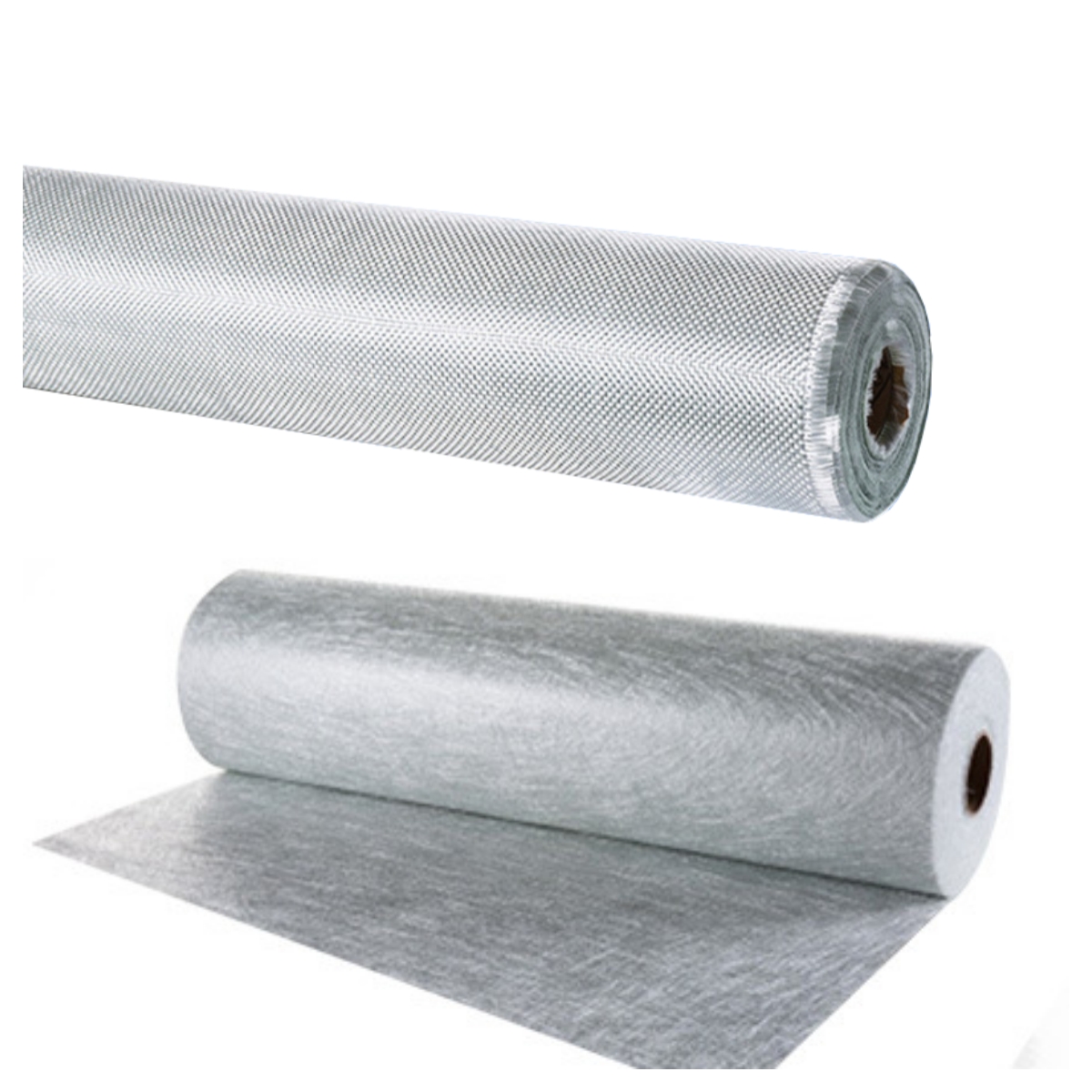

1.Structure: Fiberglass cloth, also known as fiberglass fabric, is a woven material made by interlacing individual glass fibers in a crisscross pattern, similar to traditional fabrics. It has a more regular and uniform appearance with fibers running in both the warp (lengthwise) and weft (crosswise) directions.

On the other hand, fiberglass mat, also called fiberglass matting or chopped strand mat (CSM), is a non-woven material made from randomly oriented glass fibers. The fibers are typically held together with a binder, resulting in a loose and fibrous structure.

2.Manufacturing Process: Fiberglass cloth is produced through a weaving process, where individual glass fibers are arranged and interlaced using specialized looms. The weaving process allows for precise control over the fabric's weight, thread count, and pattern.

Fiberglass mat, on the other hand, is manufactured by chopping continuous glass fibers into short strands and then distributing them randomly on a conveyor belt. The chopped strands are then bonded together using a binder material to form a mat-like structure.

3.Application: Fiberglass cloth is commonly used in applications where a smooth and uniform surface finish is desired, such as in boat construction, surfboards, aerospace components, and high-performance composites. It is suitable for applications that require more structural rigidity and dimensional stability.

Fiberglass mat, with its random fiber orientation and greater bulk, is often used as a reinforcement material in applications where conformability and ease of molding are important, such as in the production of fiberglass panels, automotive parts, pipes, and tanks.

TFcomposite supplies fiberglass cloth and fiberglass mat, you can contact us.